This is my old, very old 3d printing page. I keep it online becasue I have posted messages here and there that link to images that are on this page.

My current 3D printing website is www.davesmrs.com

Dave Yale's Adventures in 3D Printing

This website is being replaced. Visit the new website (getting closer to completion all the time) at www.davesmrs.com Dave's Model Railway Stuff. I am no longer adding listings for new models on this site.

I USUALLY AT THE MODEL RALROAD SHOW IN AMHERST IN JANUARY (http://www.railroadhobbyshow.com/). MY CLUB, VALLEY HO TRAK WILL BE THERE SET UP IN THE BETTER LIVING CENTER, AND I WILL BE WEARING A T-SHIRT WITH "DAVE'S MODEL RAILWAY STUFF" ON IT WHEN WALKING AROUND. I AM NOT SELLING ANYTHING AT THE SHOW AND AM NOT SET UP AS A DEALER, BUT I'D LOVE TO TALK TO ANYONE INTERESTED IN 3D PRINTING, MODEL RAILROADING, THE WEATHER, OR JUST ABOUT ANYTHING.

My email is dcyale@yahoo.com.

TO ORDER AN ITEM: Click on the item name to link to the product in my shop on Shapeways.com.

To see the results of some recent testing I did in using acetone to clean Fine Ultra Detail models, click here.

I started becoming involved with 3d printing in early 2013. I had re-started a hobby I enjoyed as a teenager, model railroading. I joined a club where each member did a four foot module using standard design specifications and joined them together at shows to make a large set up.

You can learn more about my club, Valley HO Trak at www.valleyhotrak.com.

Almost all of my models are for sale, and can be viewed, in my shop on the Shapeways site. THIS IS THE MOST UP TO DATE LISTING OF THE MODELS I SELL AND THIS WEBPAGE DOES NOT SHOW EVERY MODEL!

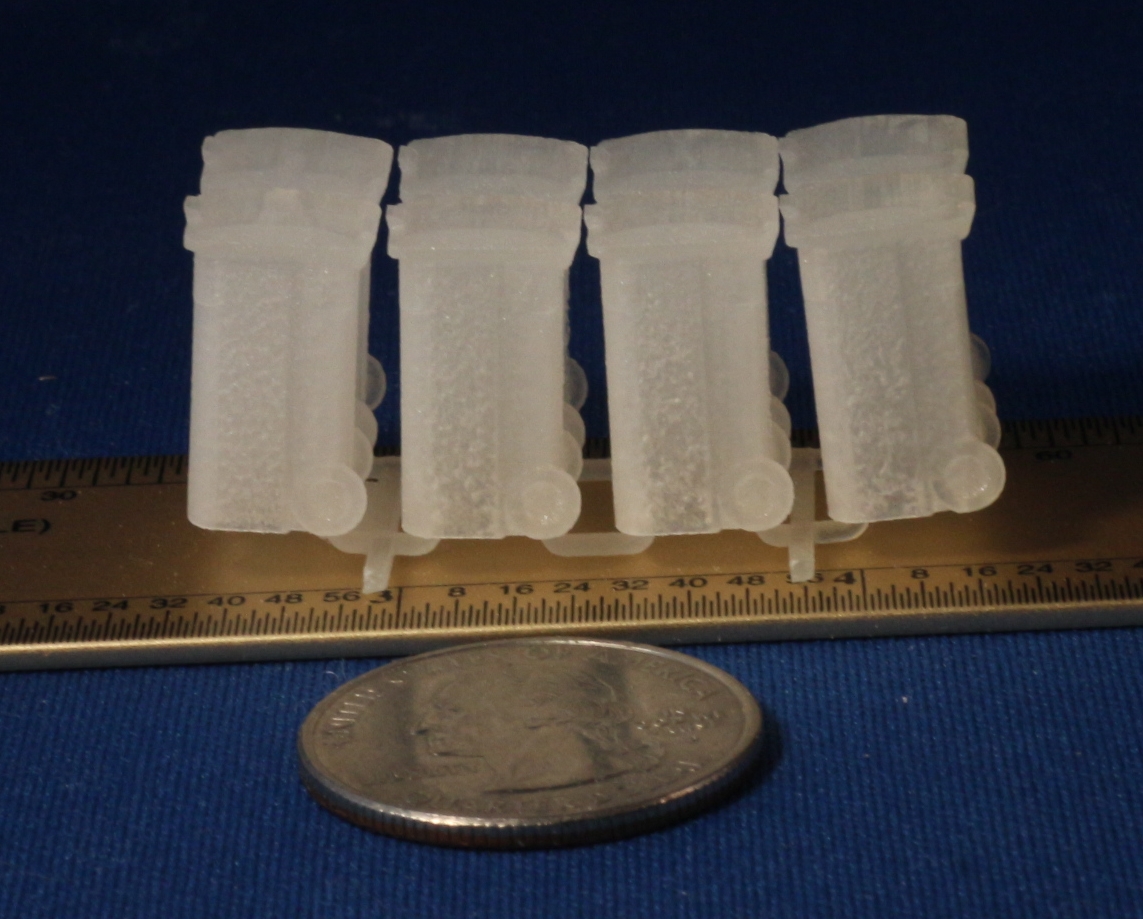

It truly is an entirely different way of doing business. When someone buys one of my designs, Shapeways prints it. There is no stock sitting somewhere. It is the ultimate "just in time" supply chain. The downside is it takes a week or two before the model ships, and the technology still has some growing pains and a model that proviously printed OK occasionally no longer prints and Shapeways rejects the order.

To order from shapeways, you should be able to click on the title of a model which will take you to the shapeways page and you can put it in your cart. Shapeways works like any other sales site, and you pay as you check out. Shapeways prints the model and ships it direct to you. It does require you to create a customer account.

If you see a picture of an item that you want and can't find it listed, let me know. My email is dcyale@yahoo.com. Sometimes I can modify a model, or resize it for another scale, if a customer wants. However, this is strictly a side buisness. I work a regular job that pays the bills, and sometimes the time I have to devote to 3D design is limited.

Go Back to TOPTable of Contents

HO Scale Interior Details

HO scale Exterior Details

HO Scale Athrean Pullman Heavyweight Passenger Car Interiors

HO Scale Design Preservation Model (DPM) building Accessories

S Scale Interior Details

S Scale Exterior Details

N Scale Details

Cleaning and Painting Models

My Story

My Shop on Shapeways (in frame)

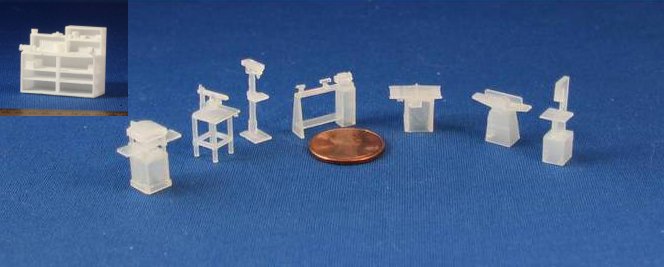

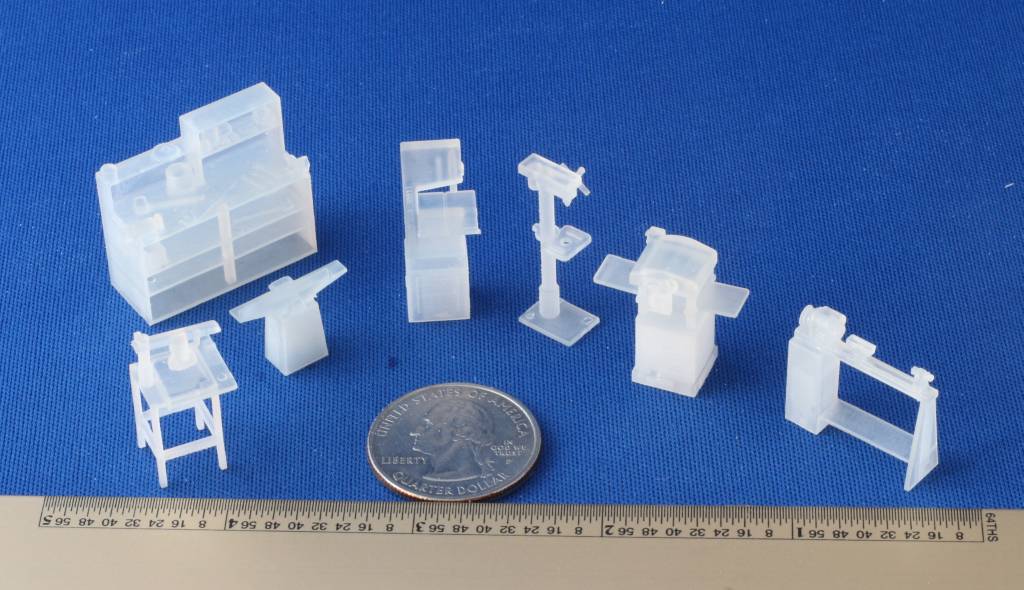

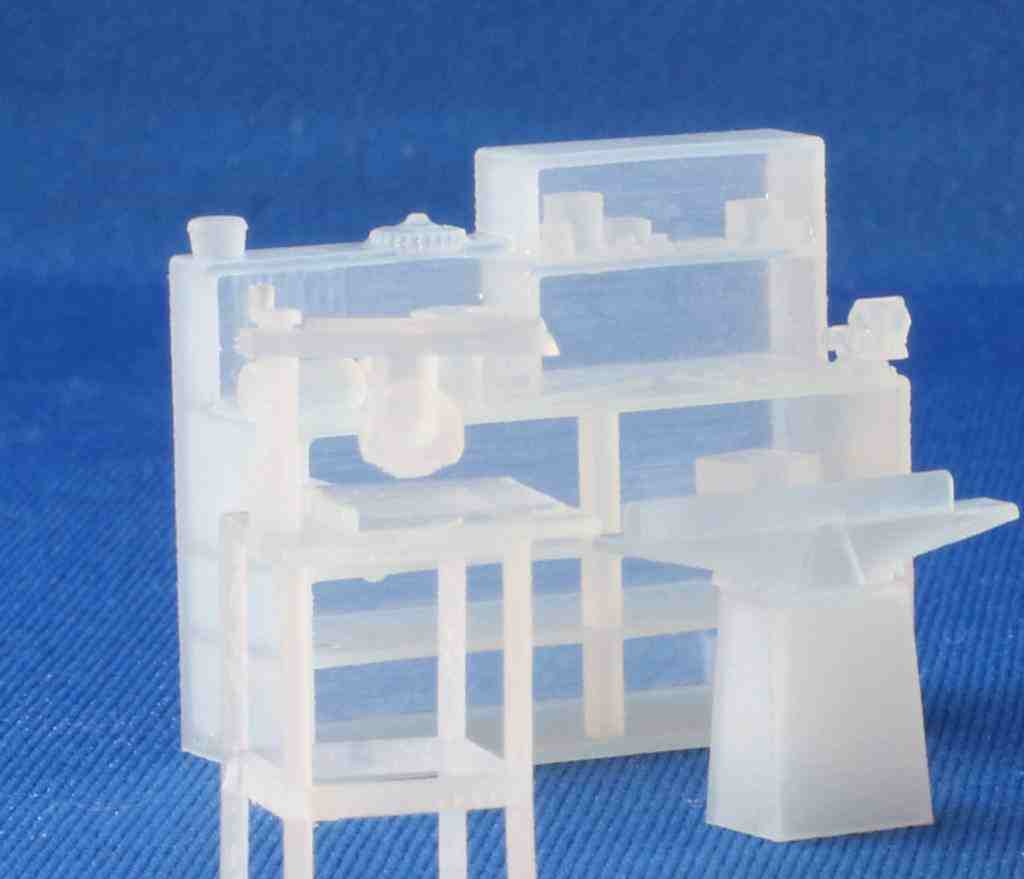

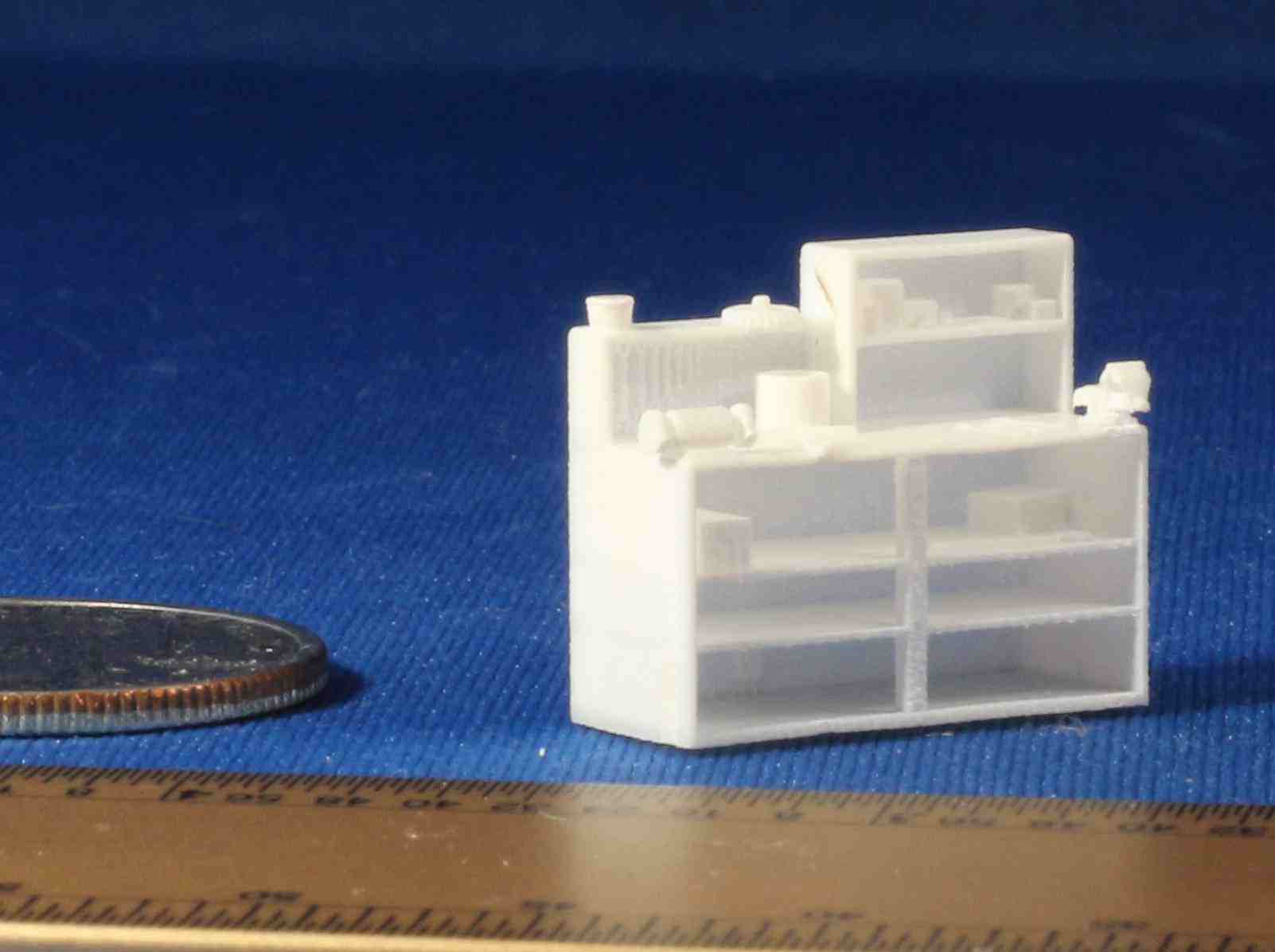

Woodworking Machinery and Workbench

Woodworking Machinery

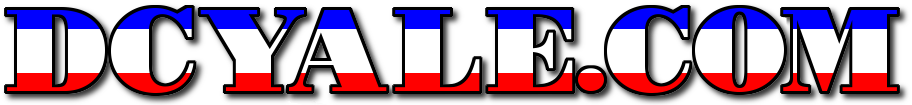

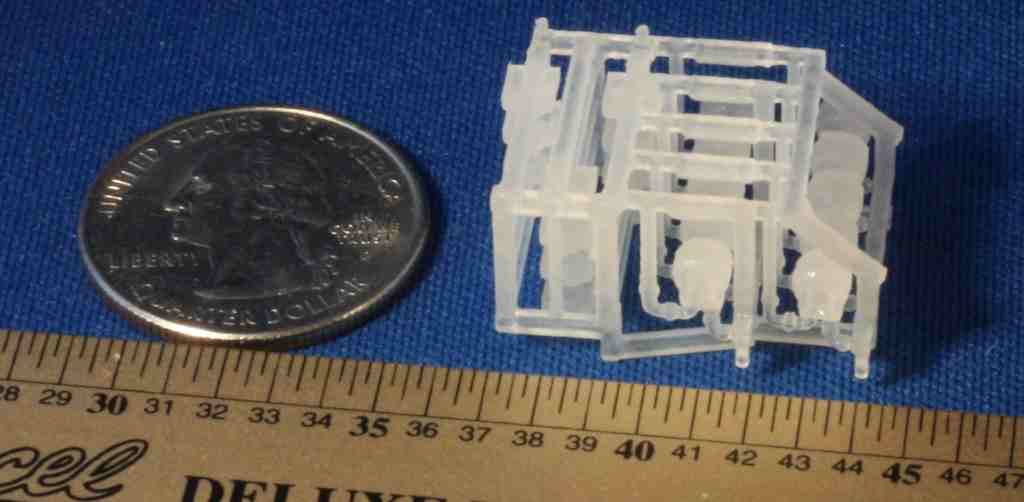

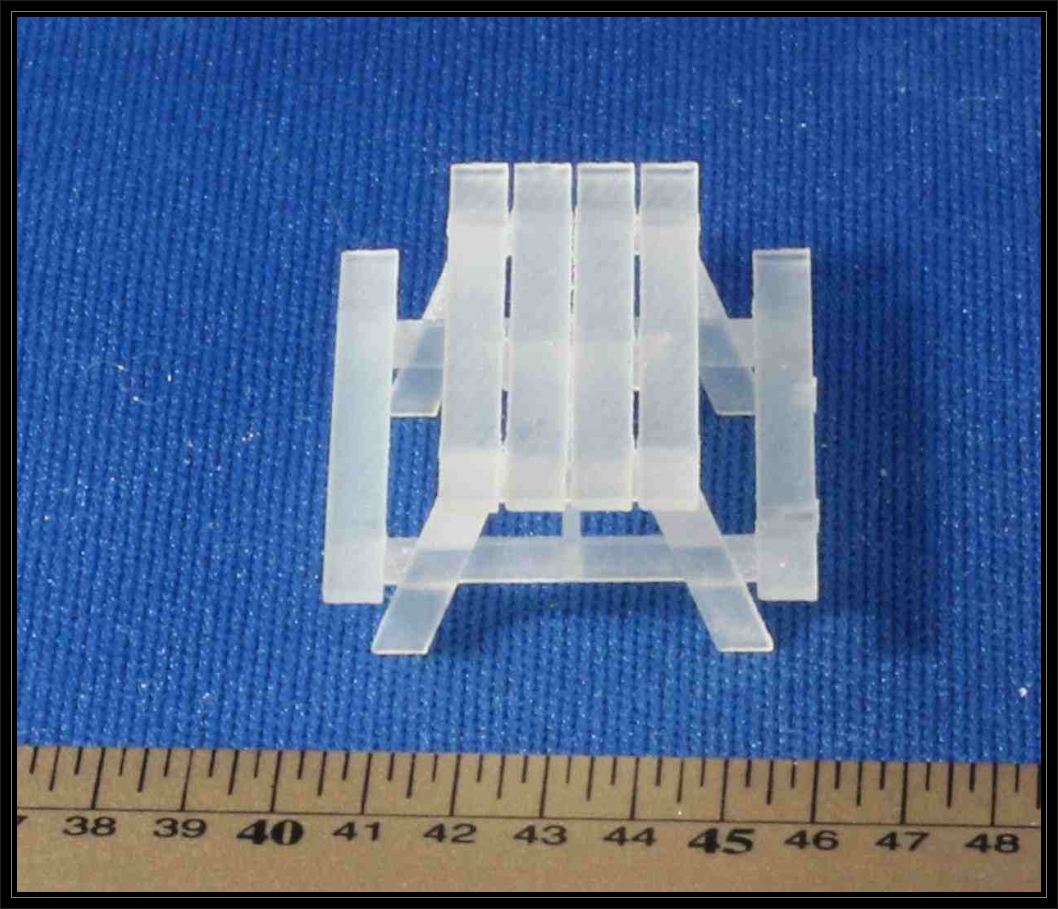

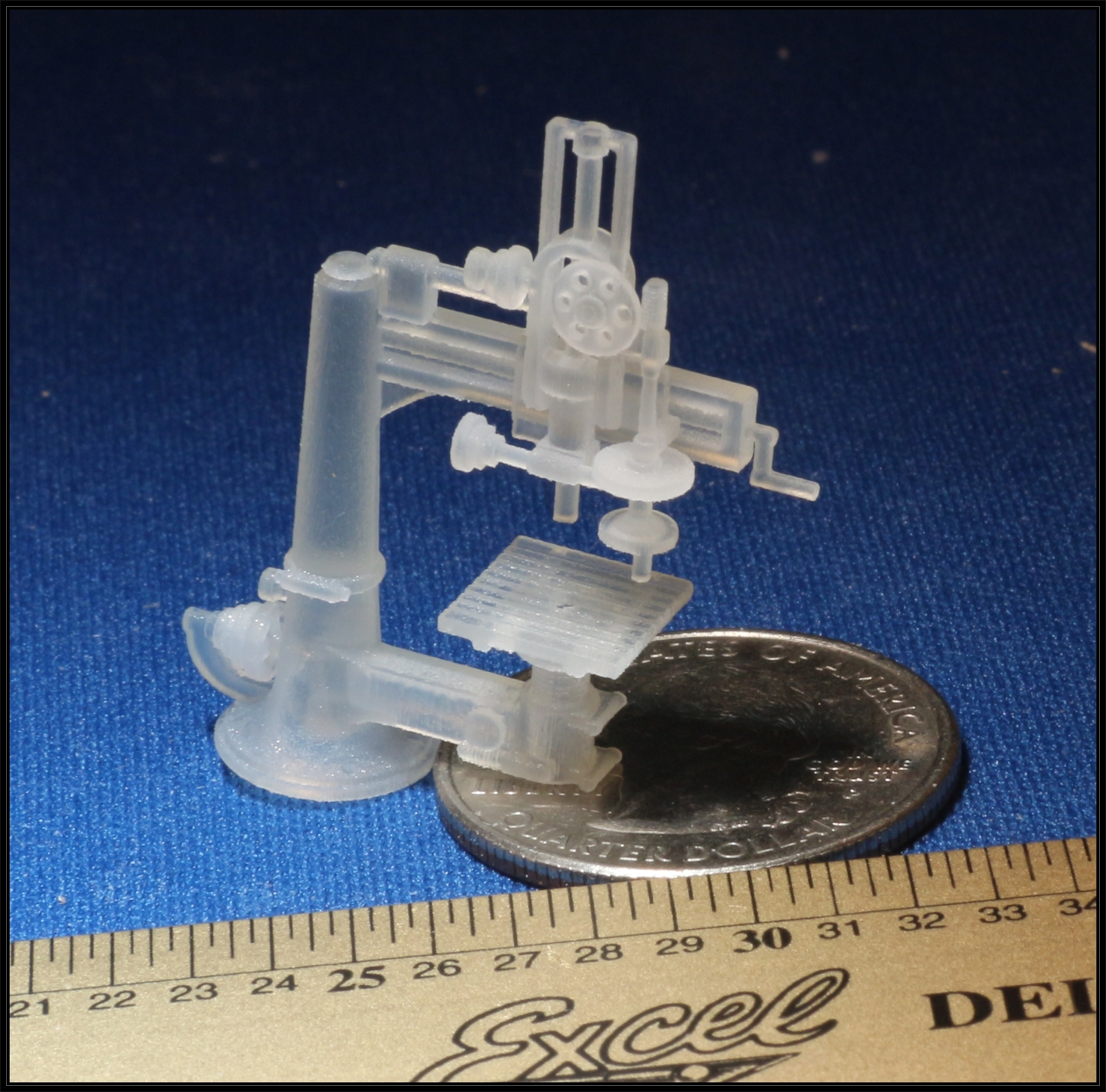

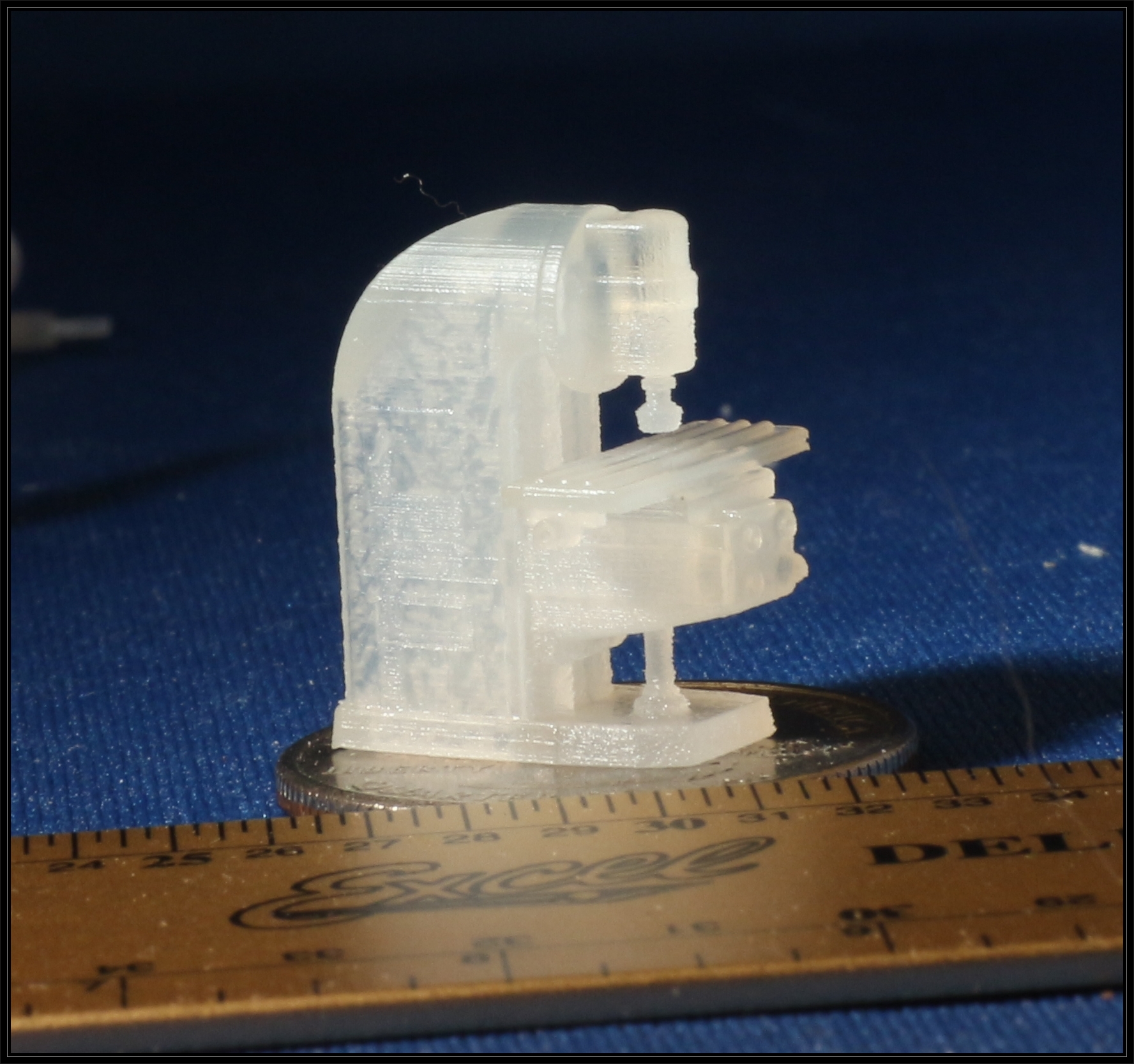

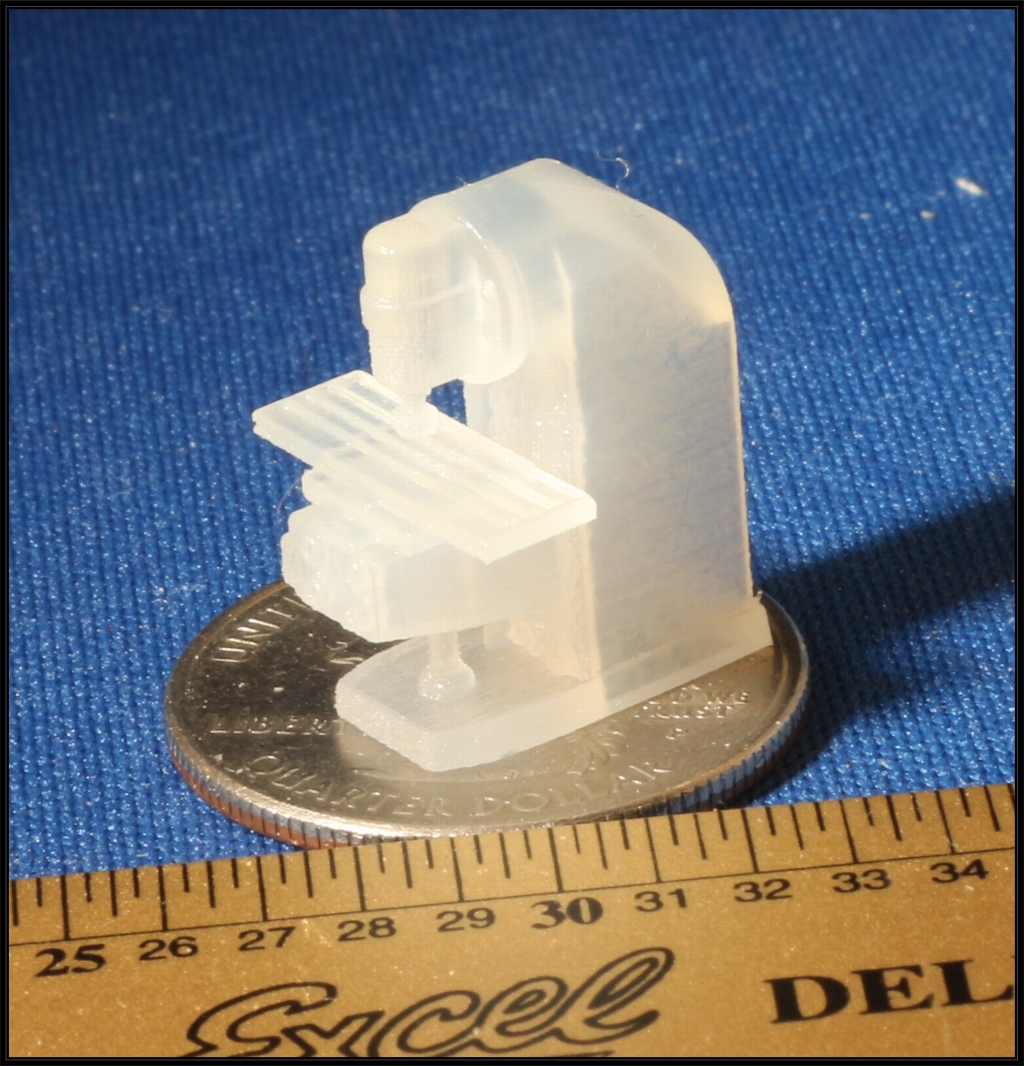

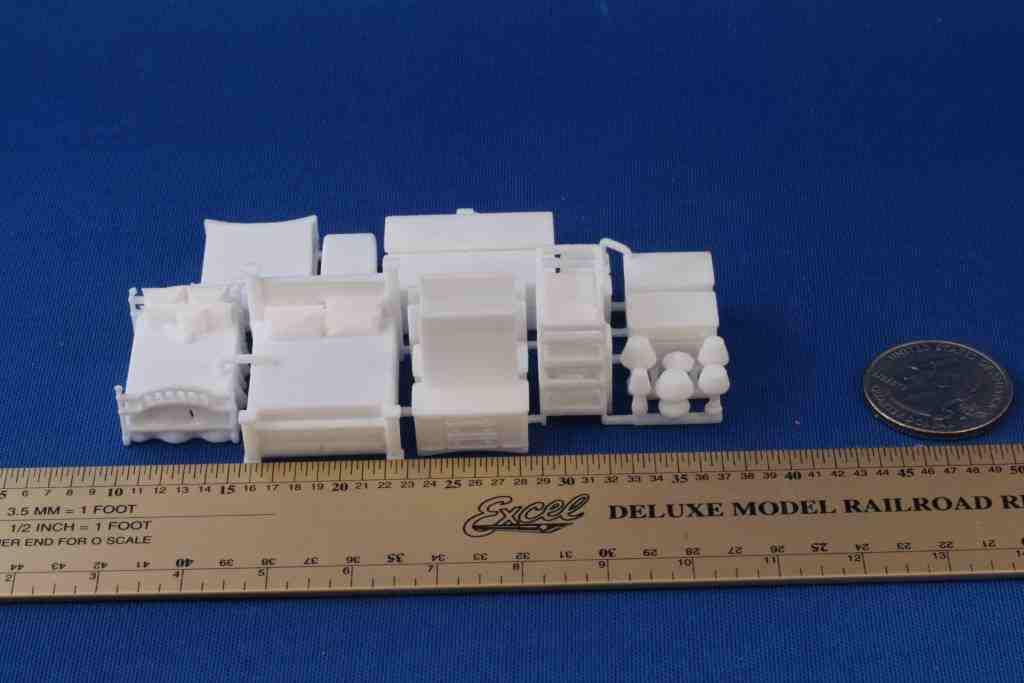

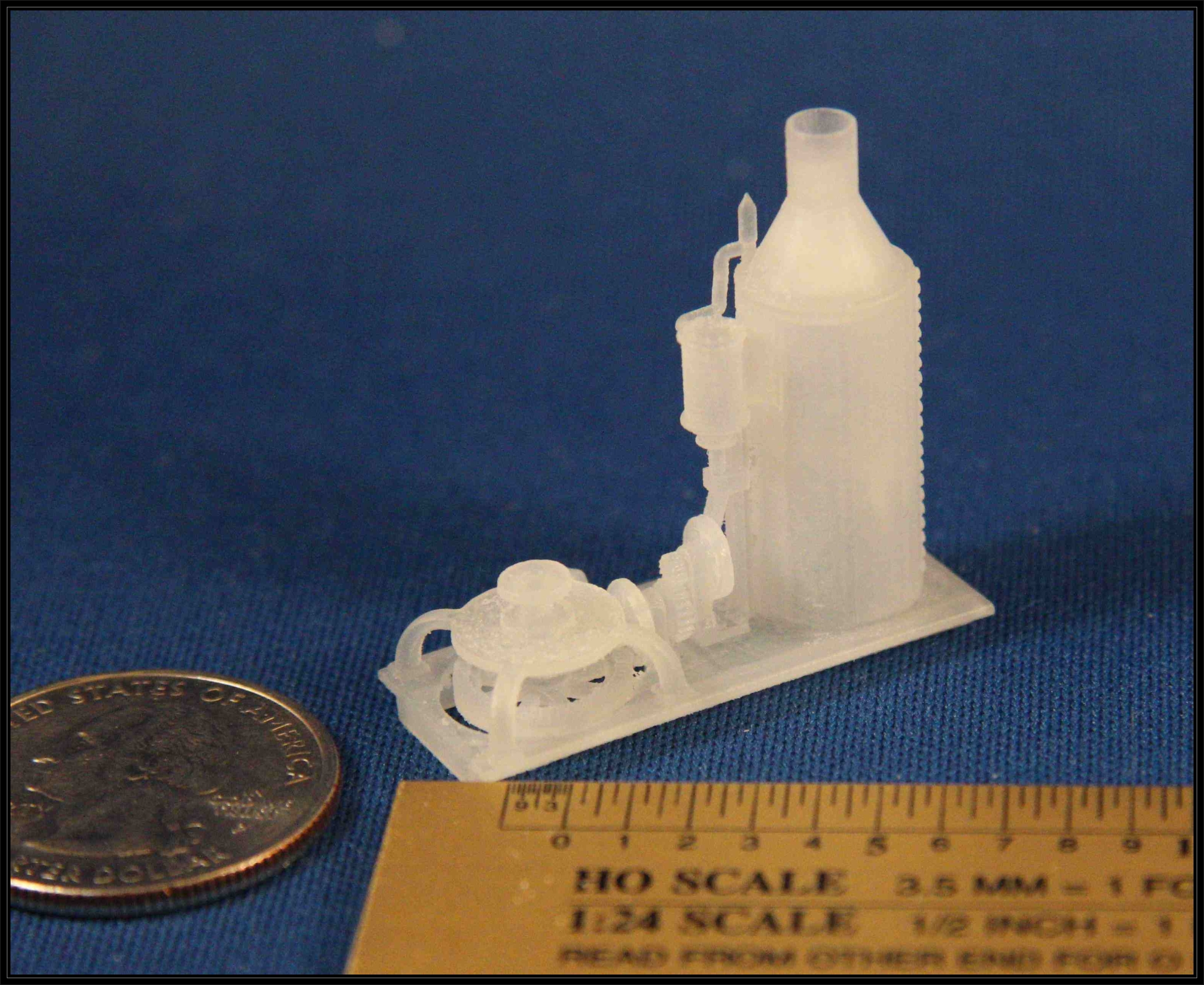

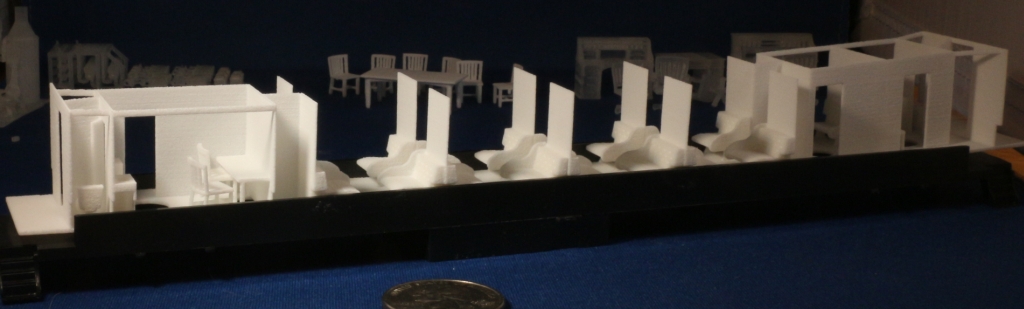

This is my most popular model. The painted models are a old version and there are some changes, as well as additional tools now.

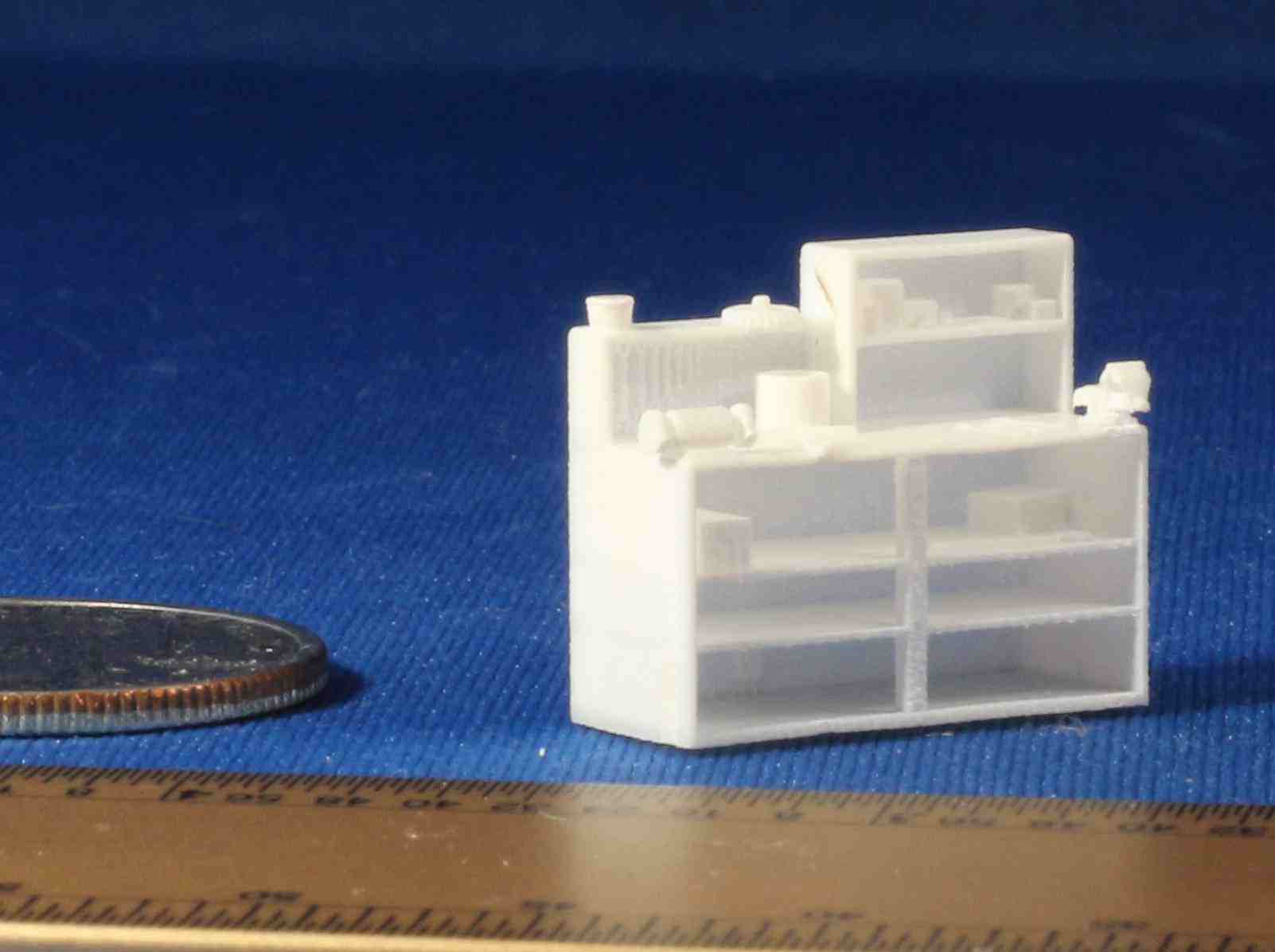

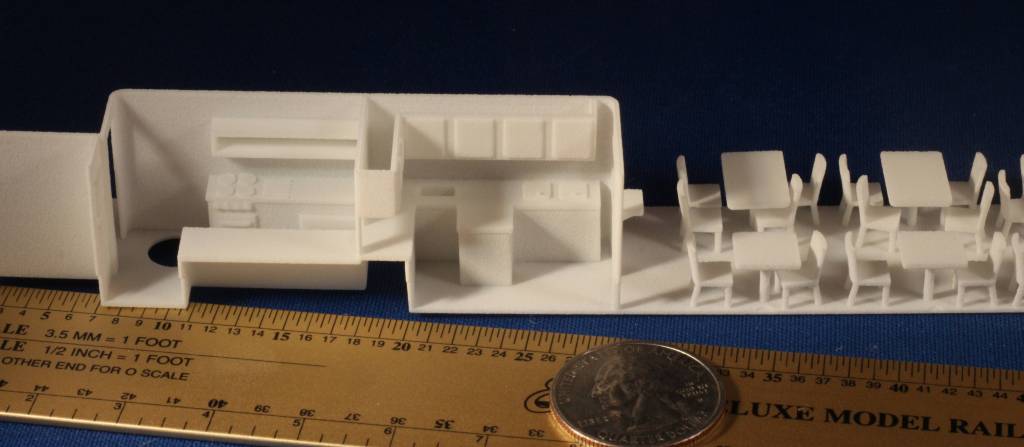

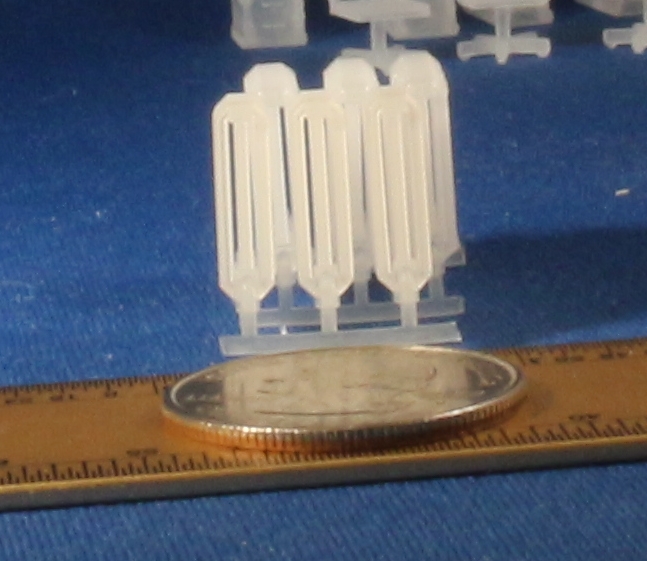

I am also adding a version with a workbench. In these pictures the workbench has been soaked in acetone for 20 minutes to clean it, and it also turns it white. The coin you can see in one photo is a quarter.

>

>

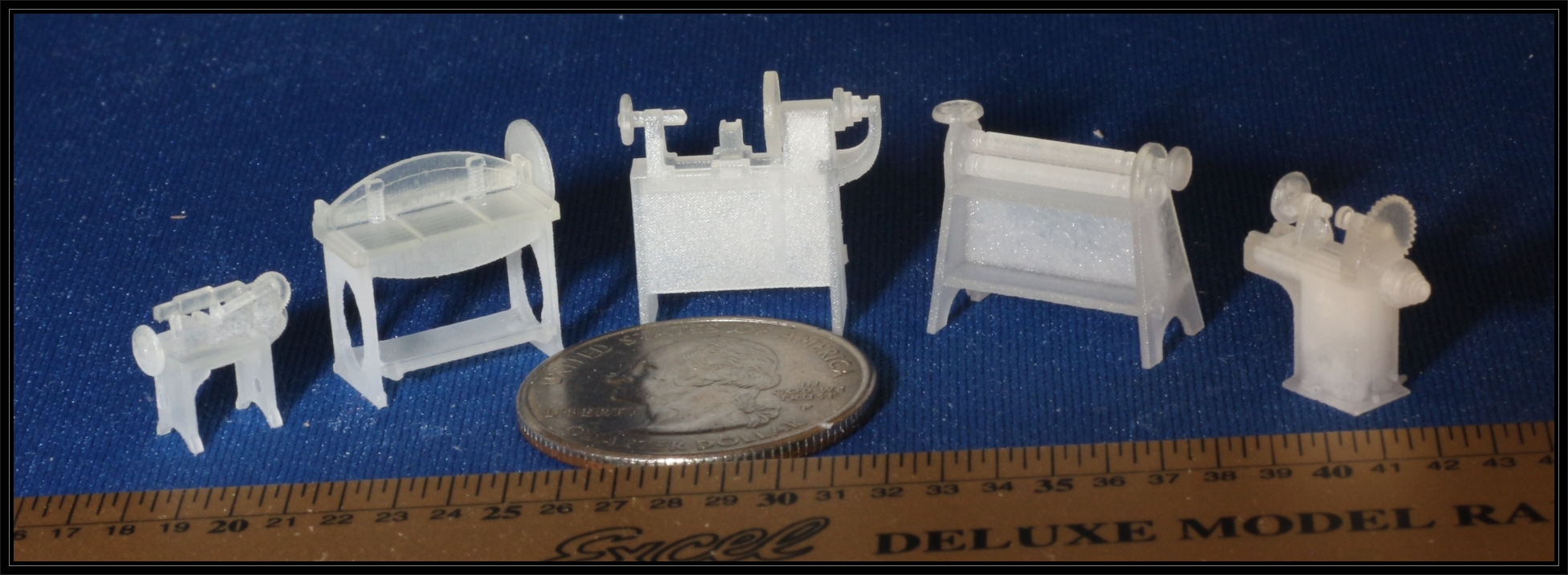

I decided that not everyone was into carpentry, and thought I'd add some machines to work in metal. Individual tools include a metal shear, a metal roller, a metal lathe, a thread cutter and a power hachsaw. These tools are designed to use an overhead power belt system, and I will be releasing a steam engine and pulleys for you to use with wire to set up a whole system.

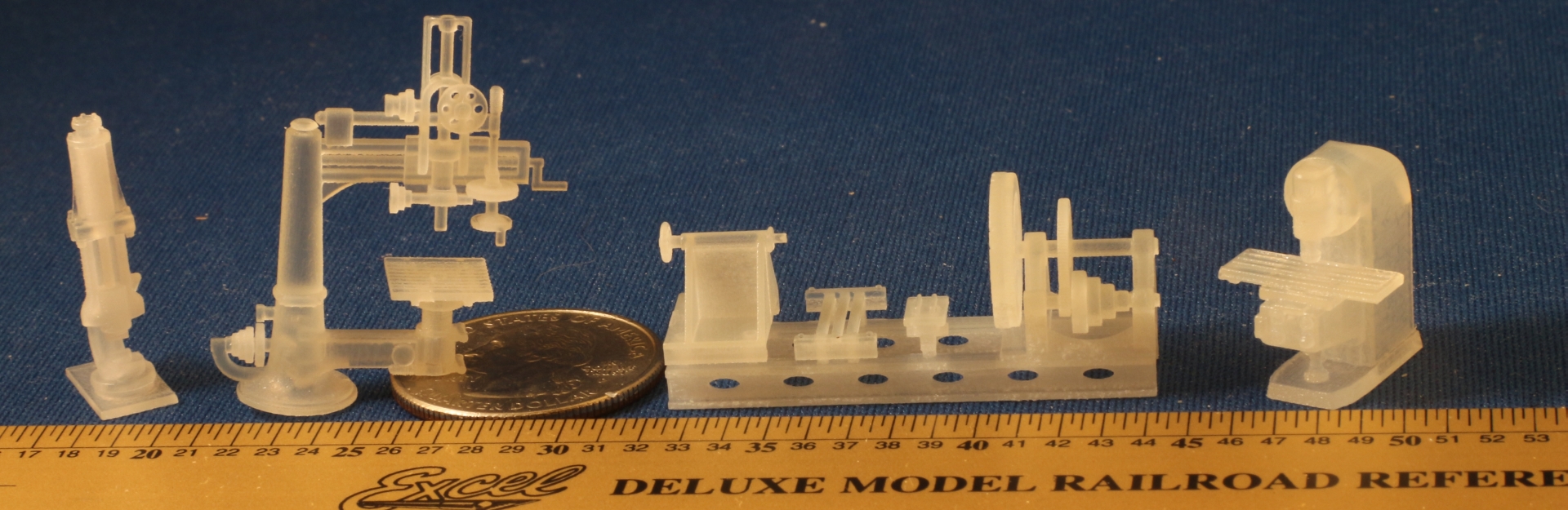

Heavy Machinery for a Car Shop, Engine House or Roundhouse

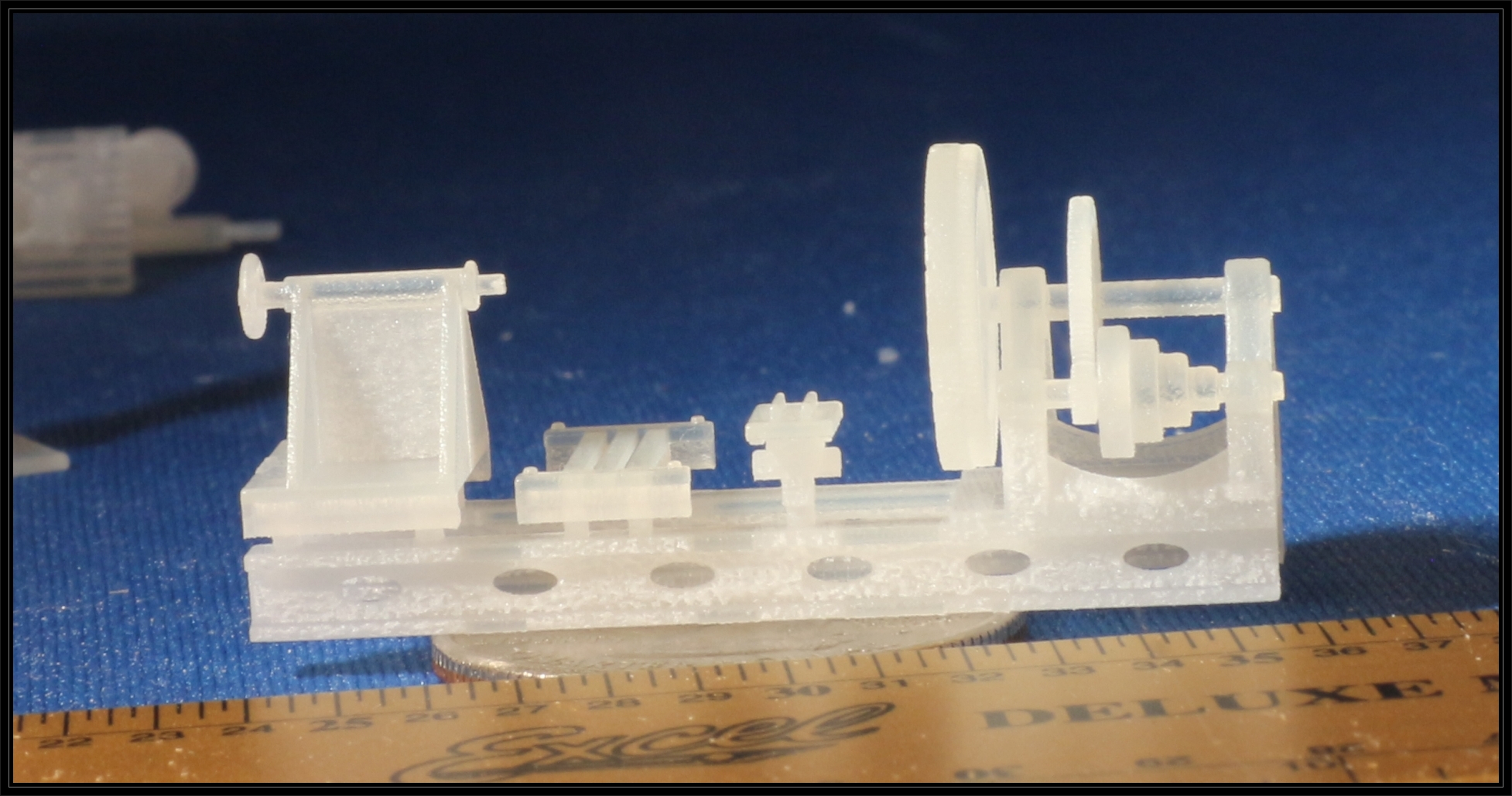

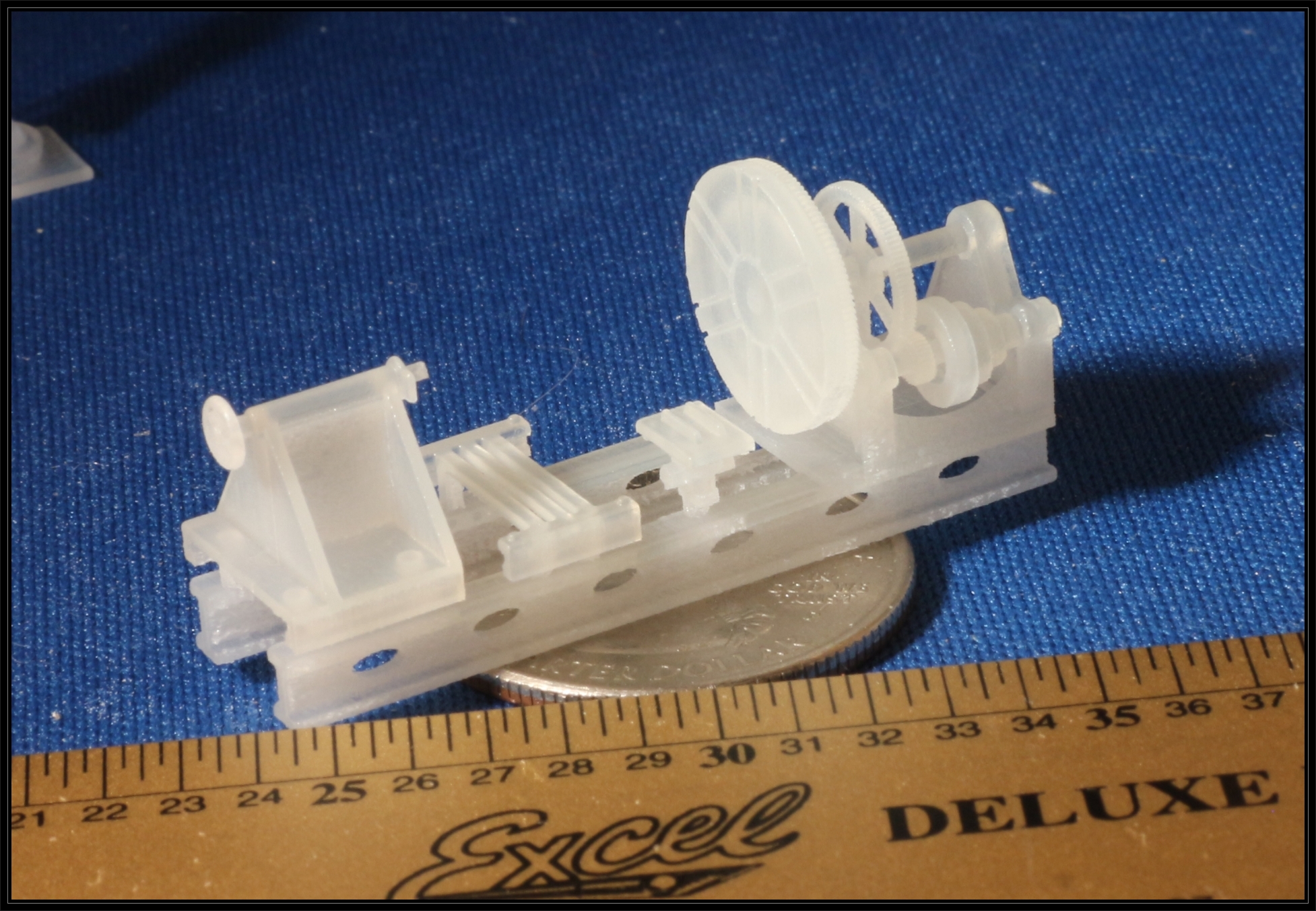

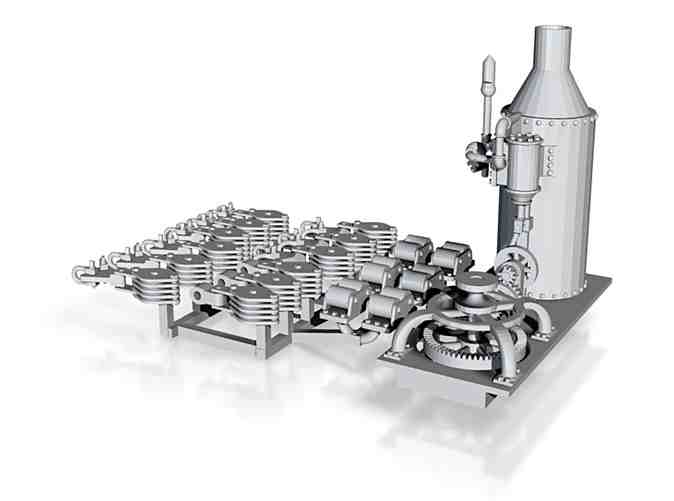

Too many roundhouses and engine houses have the doors open for the rolling stock to go in, but are almost empty. These are a good start to change that. They are mainly designed for use with an overhead belt drive system. The models are also available individually:

When you look at the pictures you may notice some missing gears and teeth. A new version has been completed and is in the test print process. Sometimes I get some unexpected results!

Based on some pictures I found online, this model requires a little careful assembly. The tailstock and tool rest need to be carefull cut from the frame with a good quality sprue cutter and ACCed into place. This allows it to be adjustable. My thought is that a wheel set could be put on the lathe with a little work.

I just like the looks of this one.

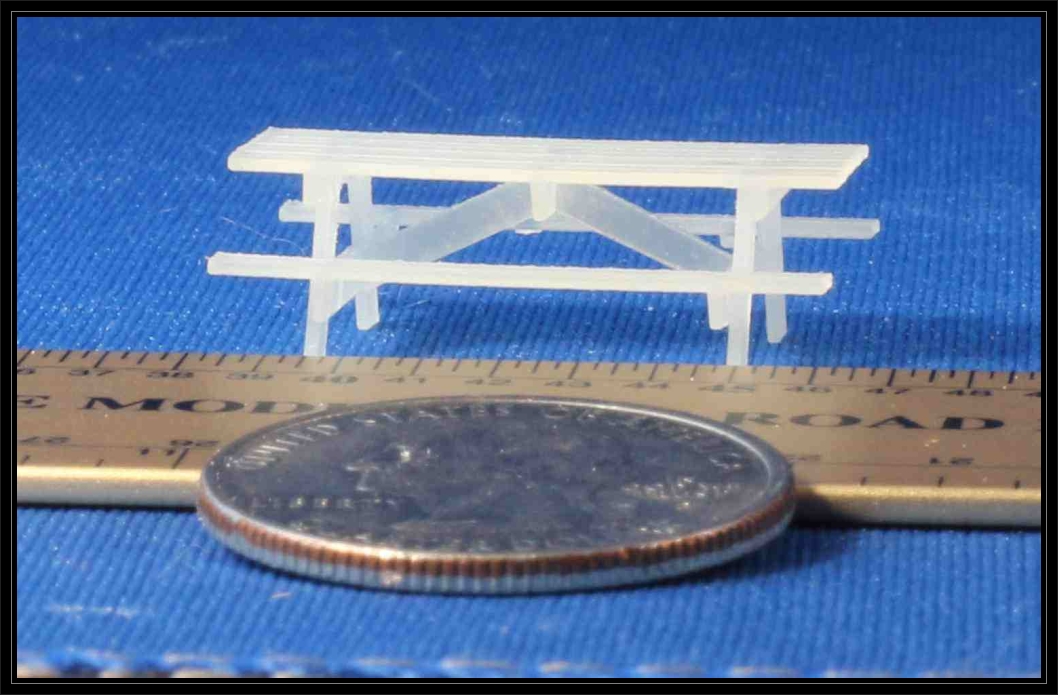

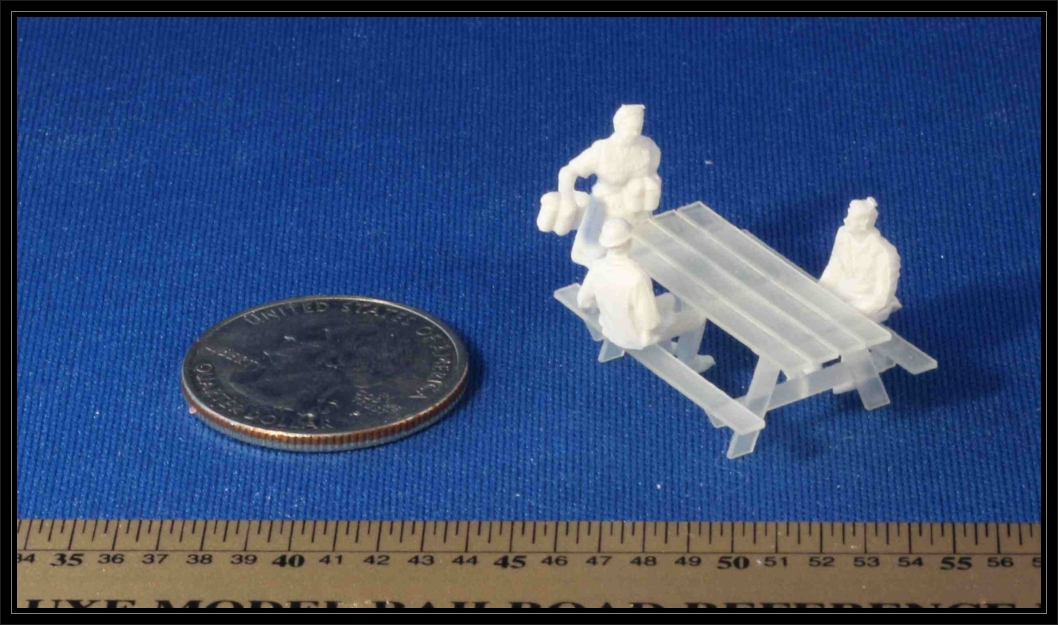

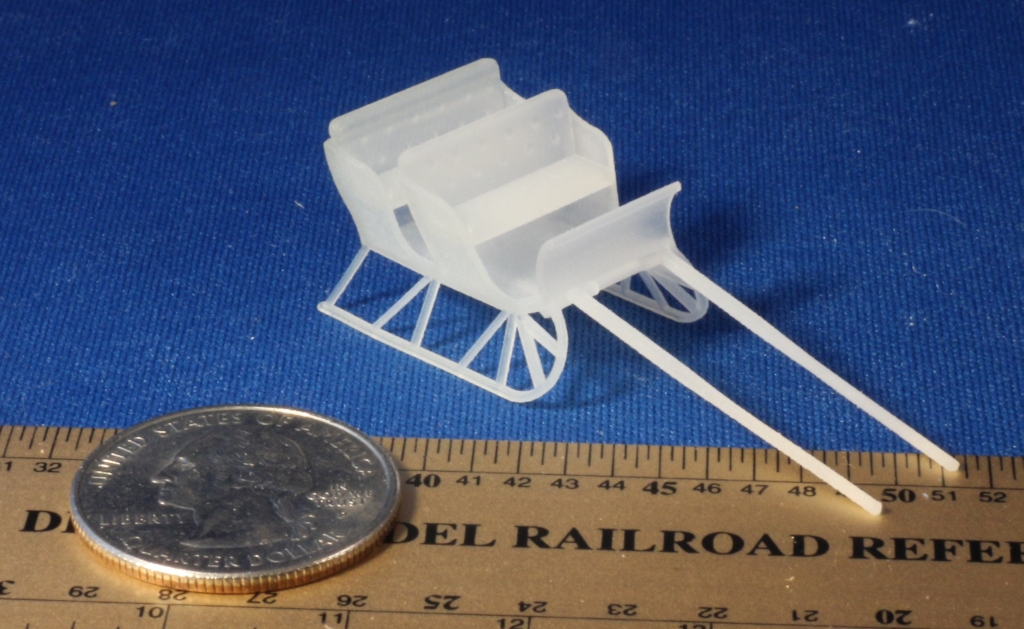

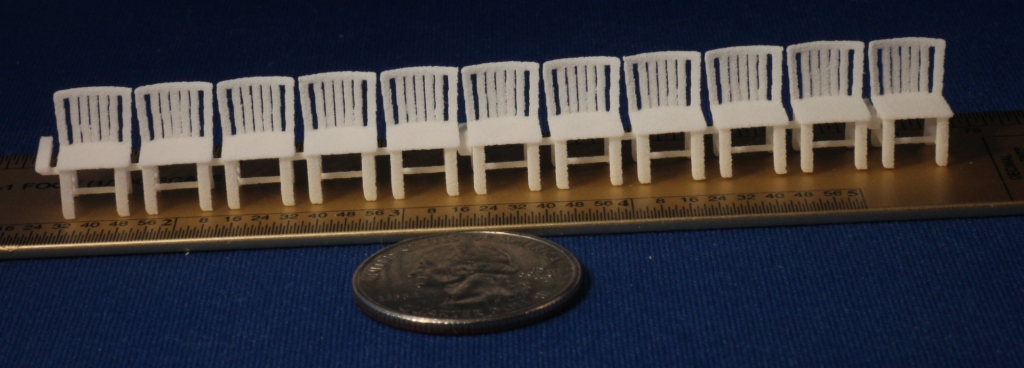

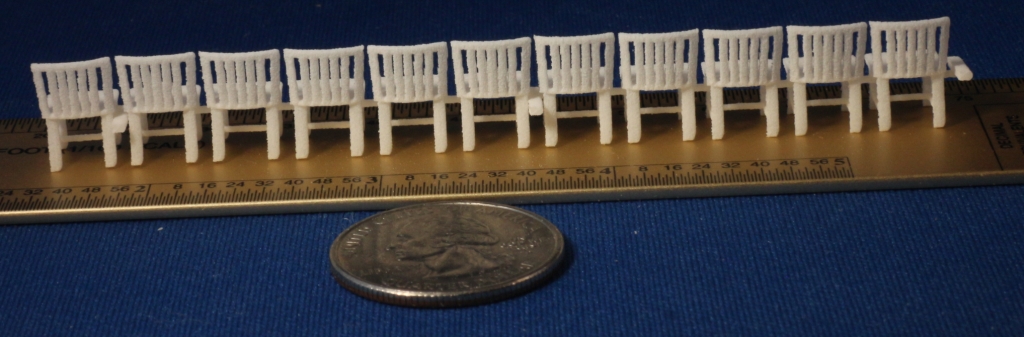

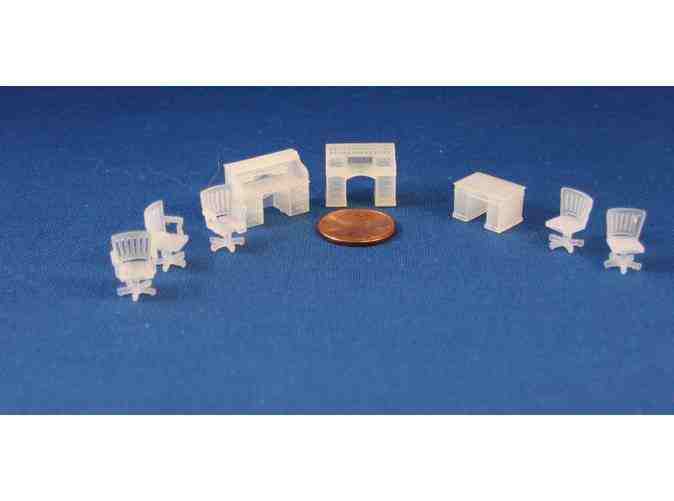

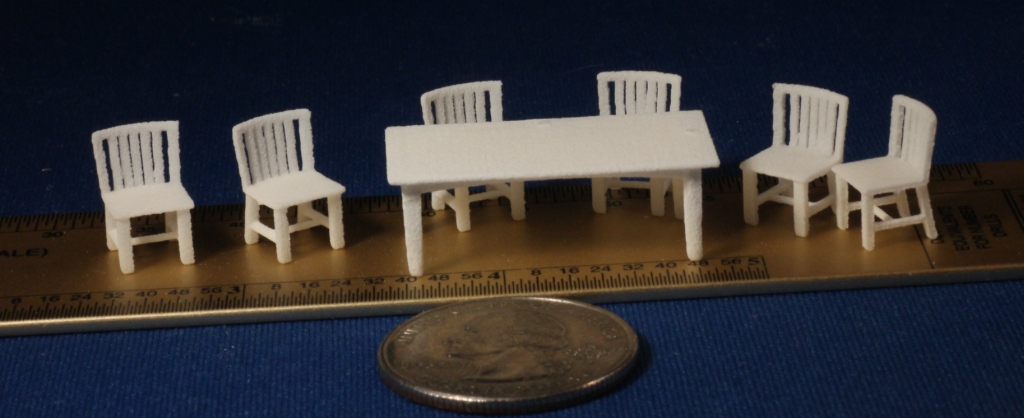

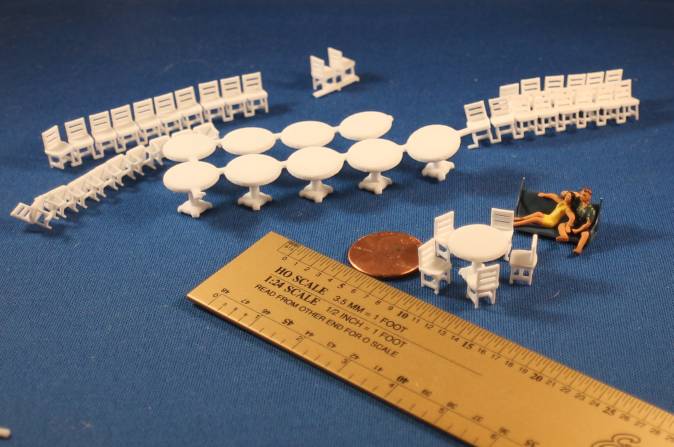

This is my second most popular model. It has extra chairs just in case one is damaged during shipping. The chairs push the present abilities of the technology to the maximum.

The style of chair has changed once again.

The style of chair has changed once again.

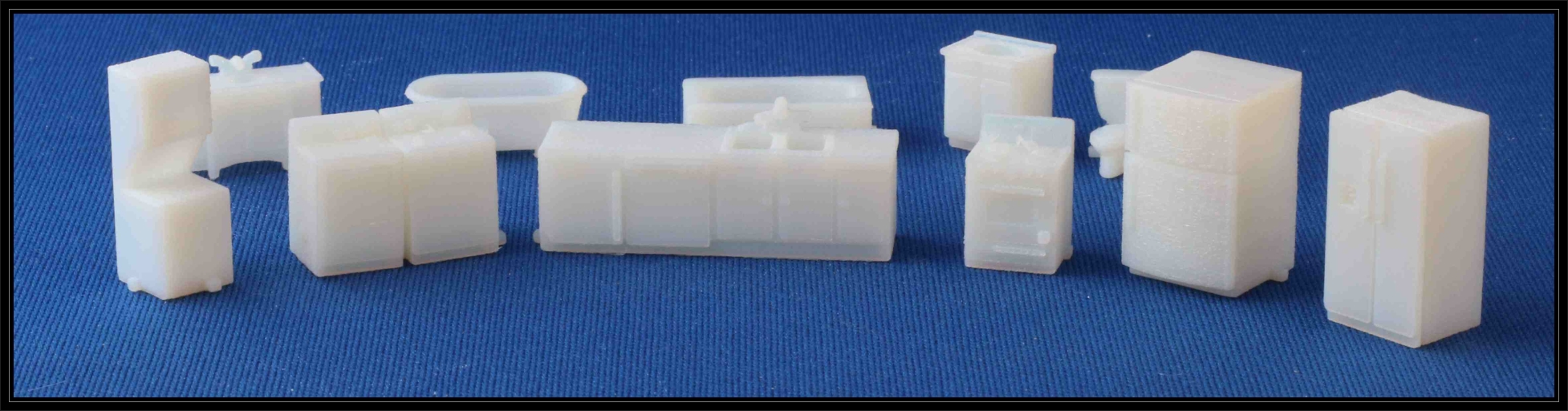

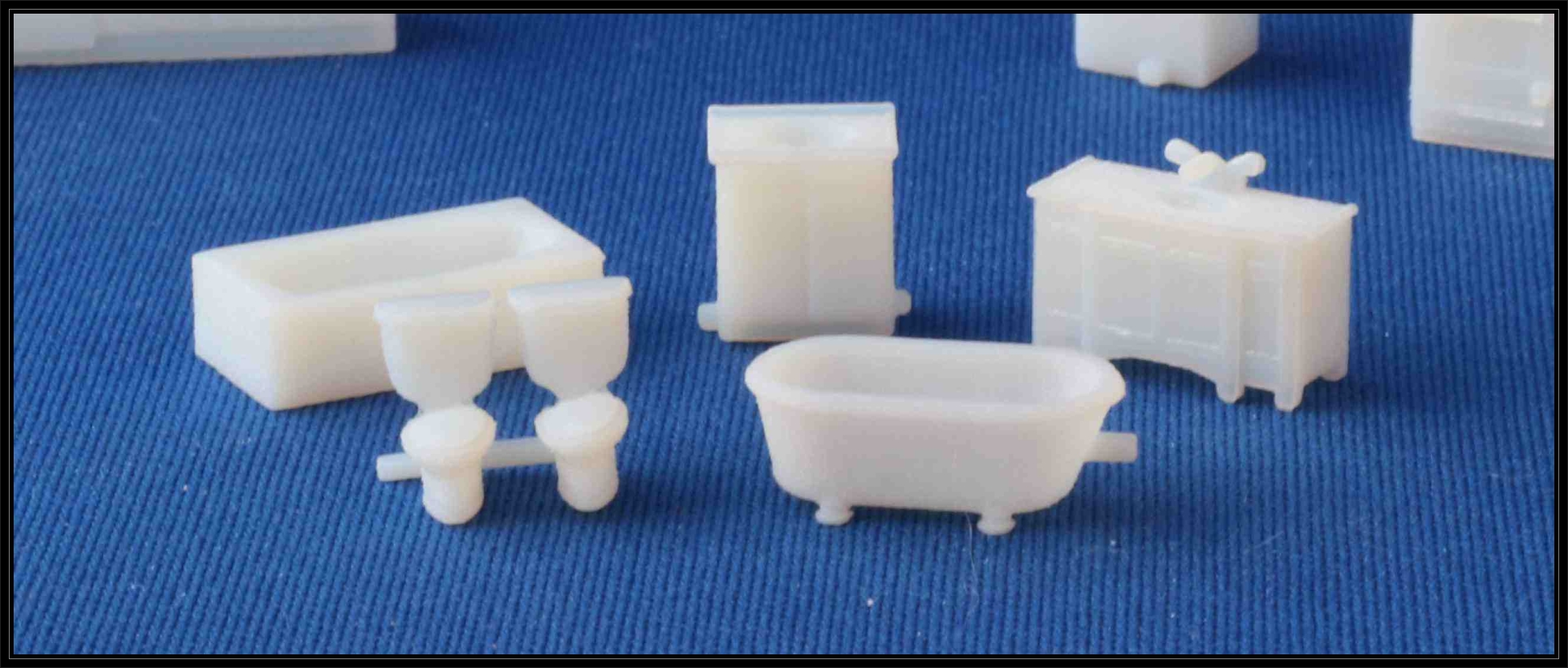

Kitchen and Bath Details in Detail Plastic

Using detail plastic is a bit more expensive, but the finish is really smooth and the details show up better.

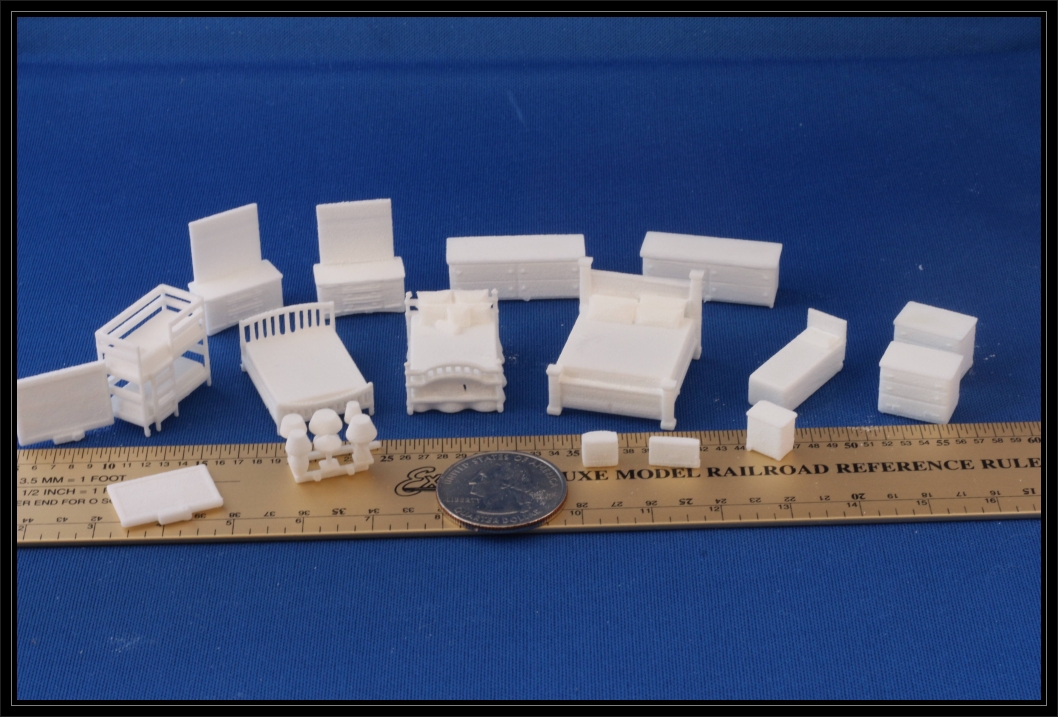

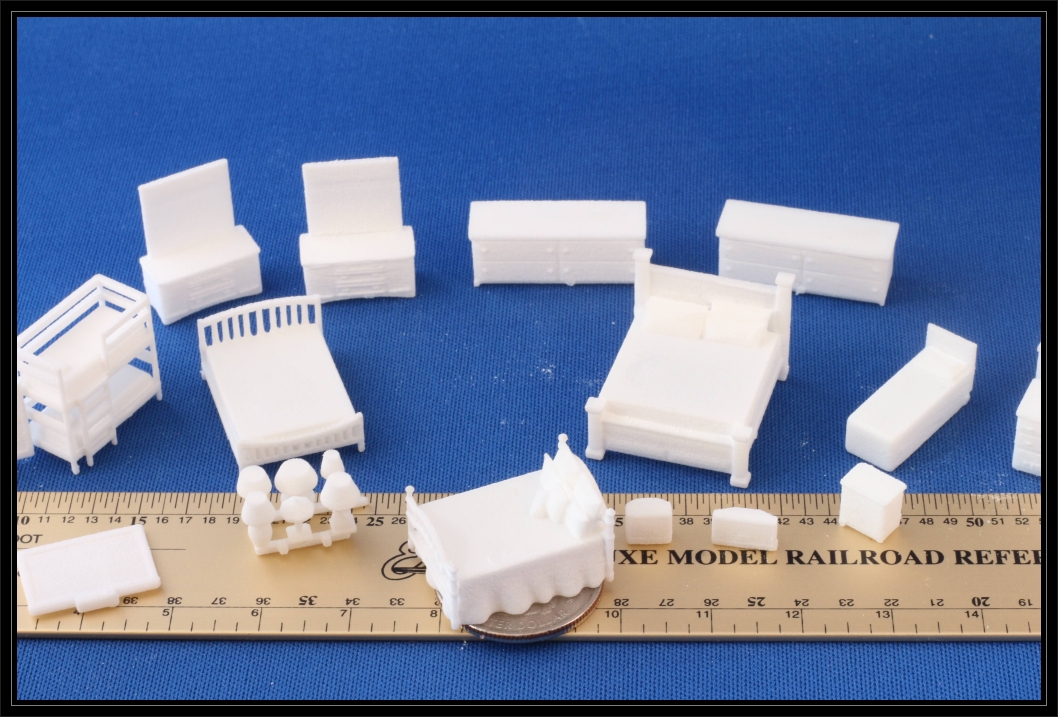

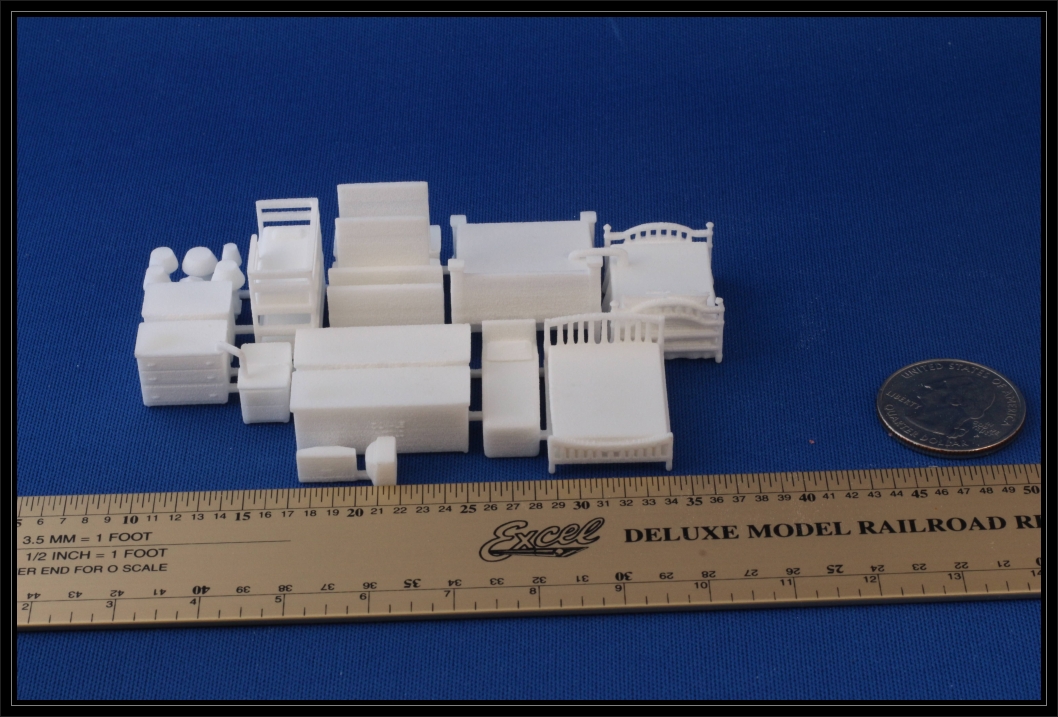

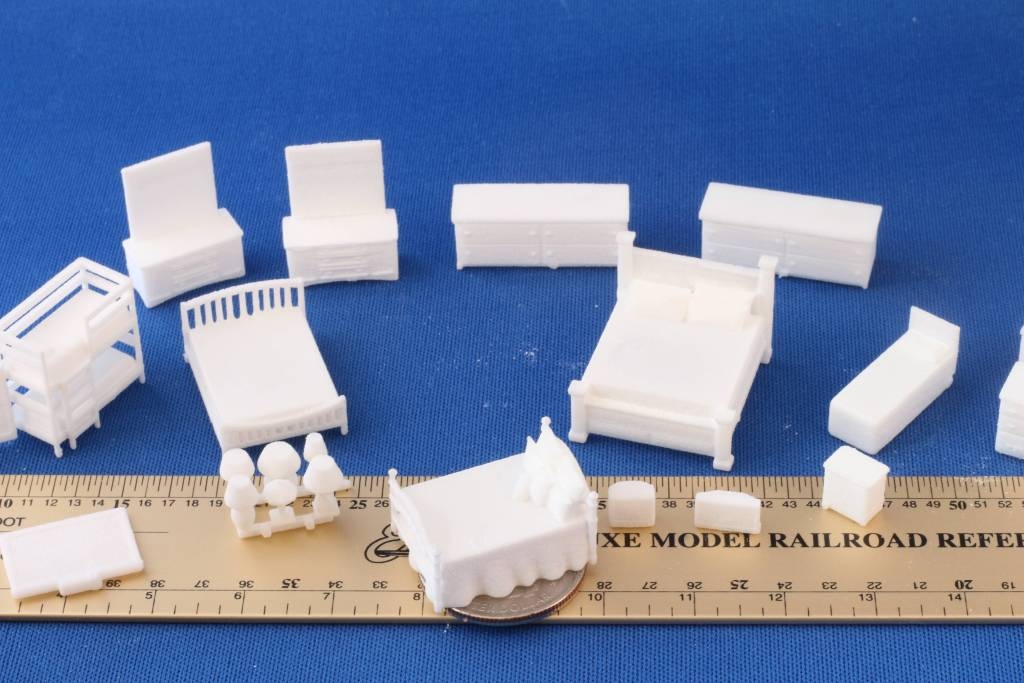

The small hole you may notice in the front of the brass bed has been fixed. If you go to my shapeways shop I also have smaller collections of bedroom furniture if you only need to fill one room.

Donkey Engine and Logging Pulleys

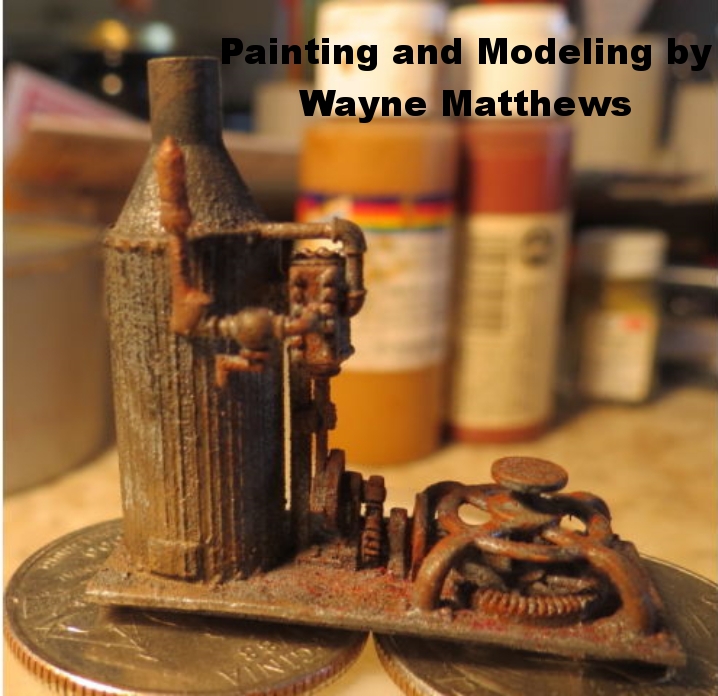

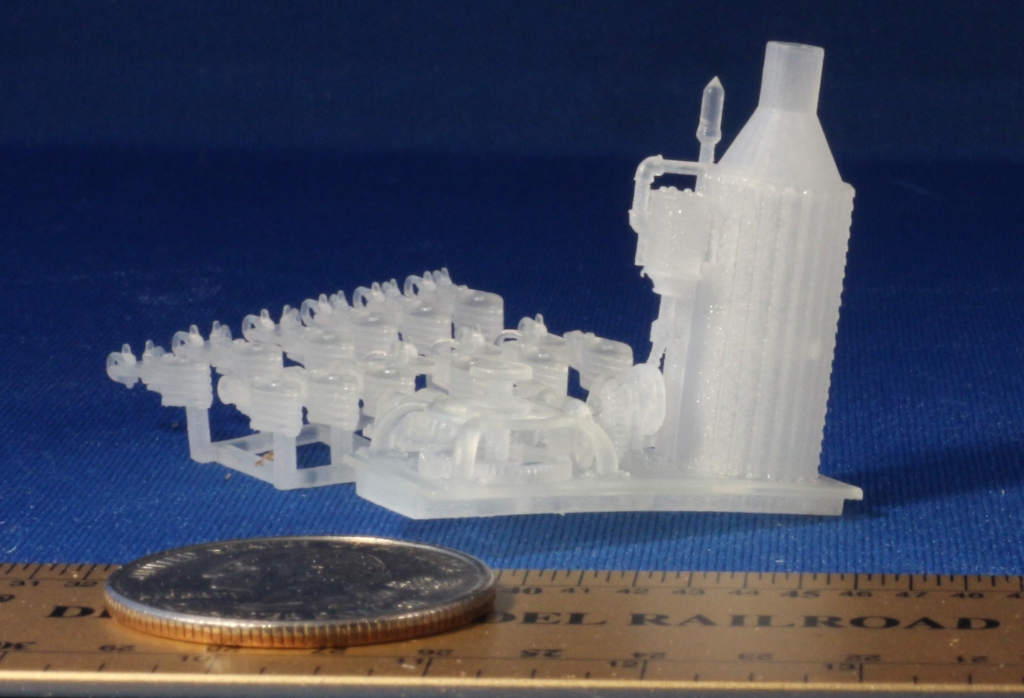

The test print came in a little warped, and there is some vertical banding on the boiler of the donkey engine. I am trying to figure that out.

Some pictures show a prior version.

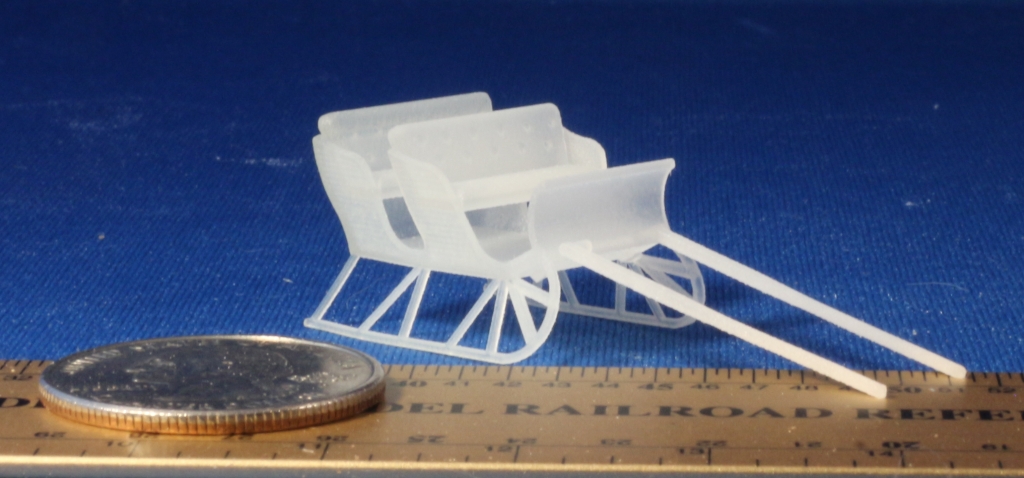

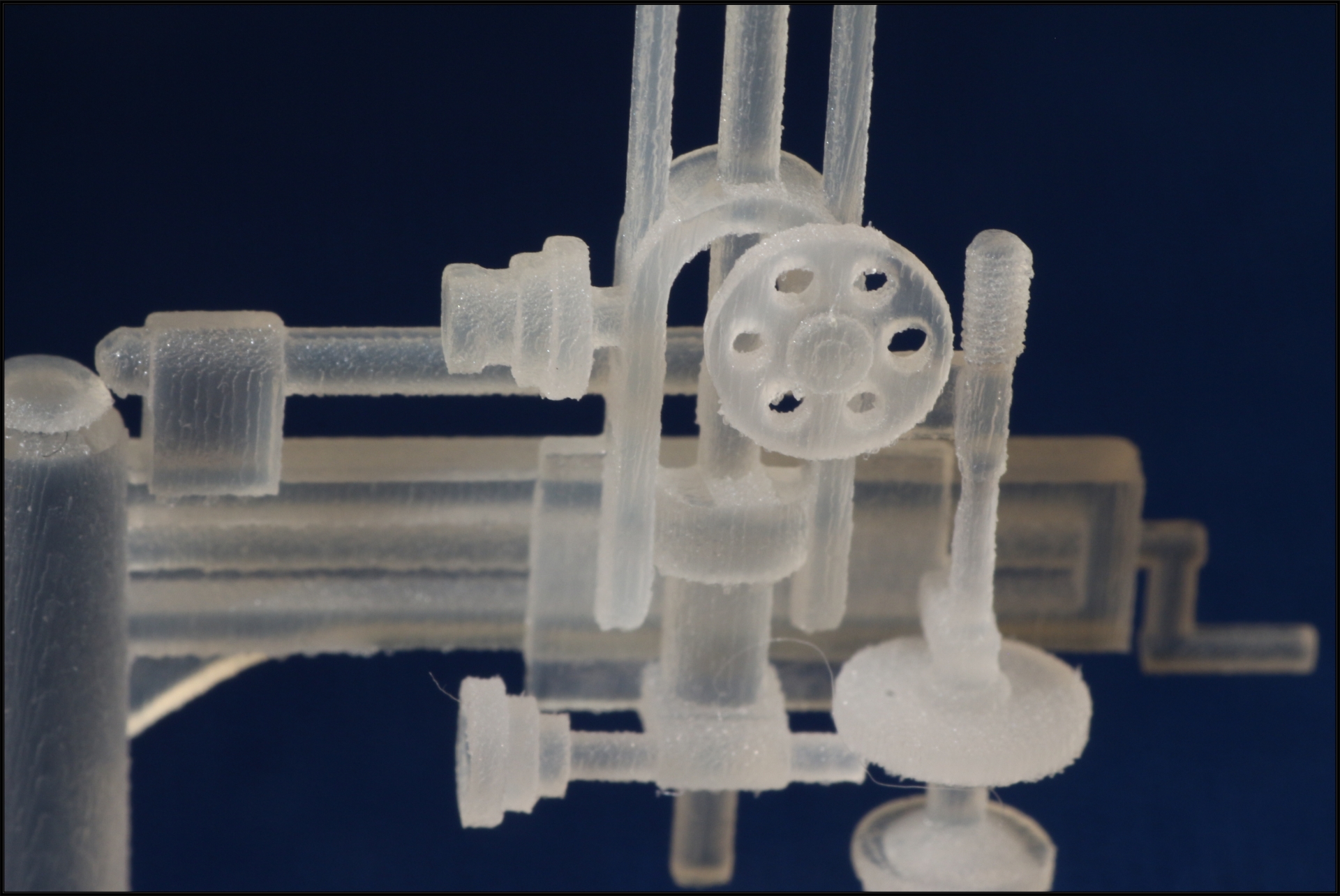

I started out playing with my 3D design software, trying to figure out different things, and ended up with this model. I don't model this time frame, nor do I model logging, but I love this one. The detail amazes me. The smaller gear is 1/10 inch in diameter, and has visible teeth.

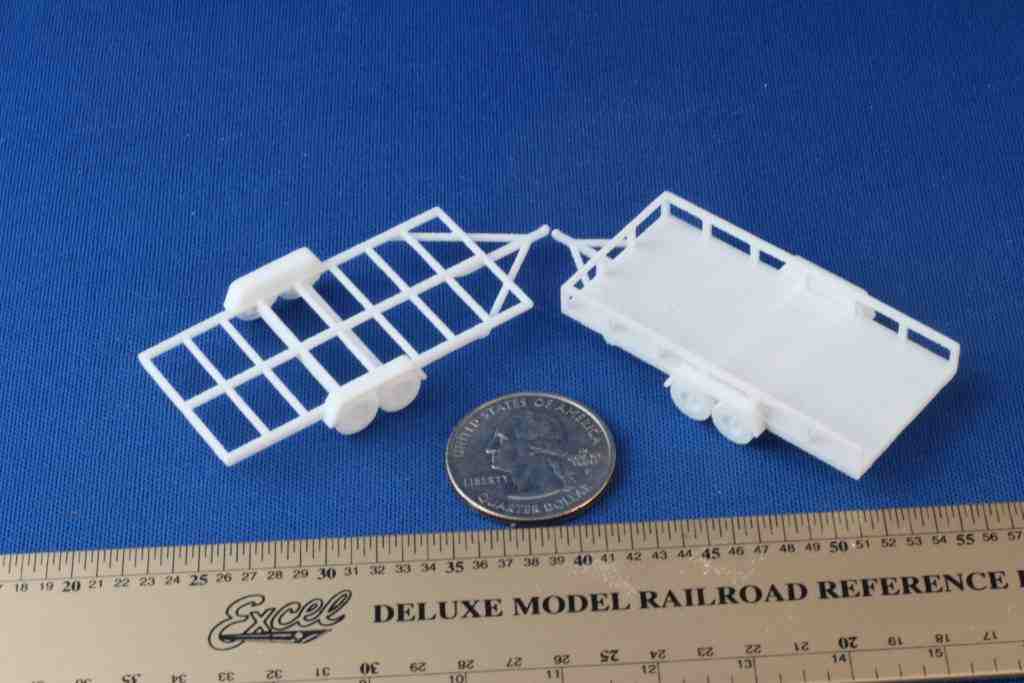

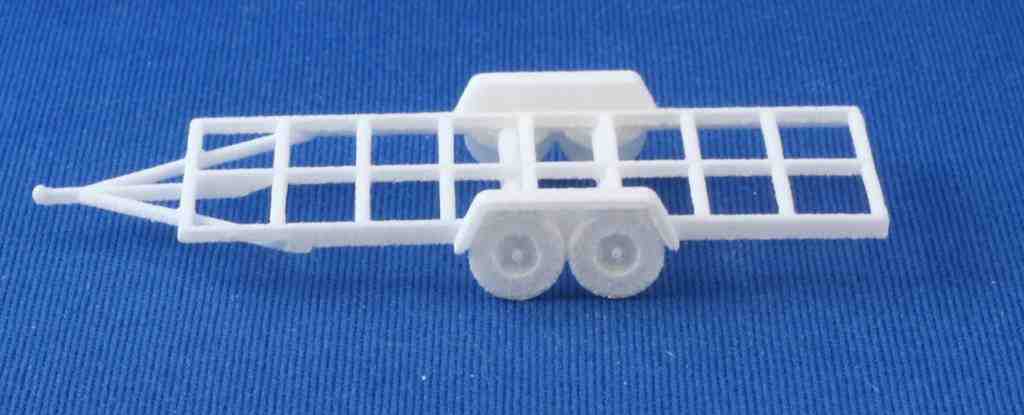

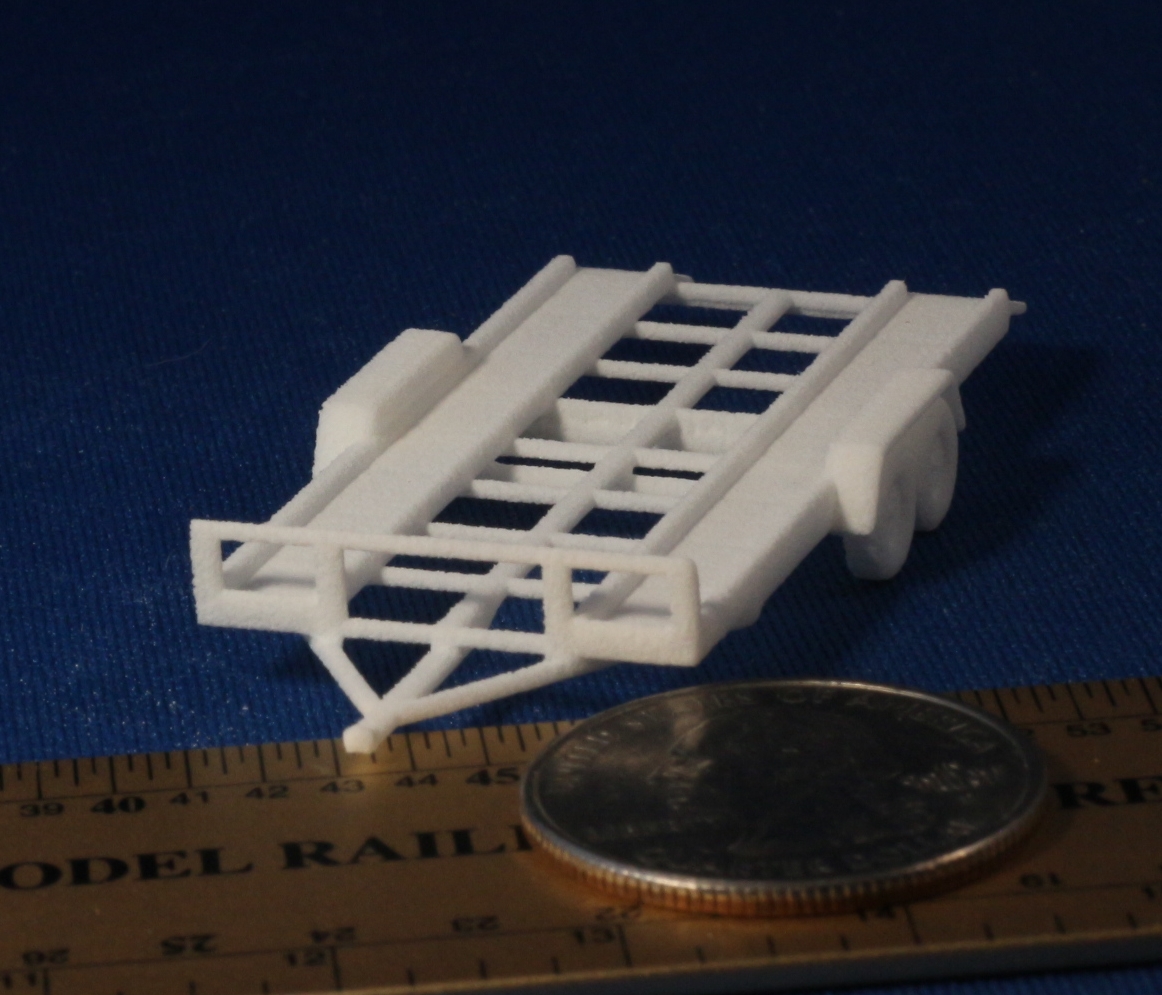

Trailer Frame

Flatbed Trailer

Car Trailer

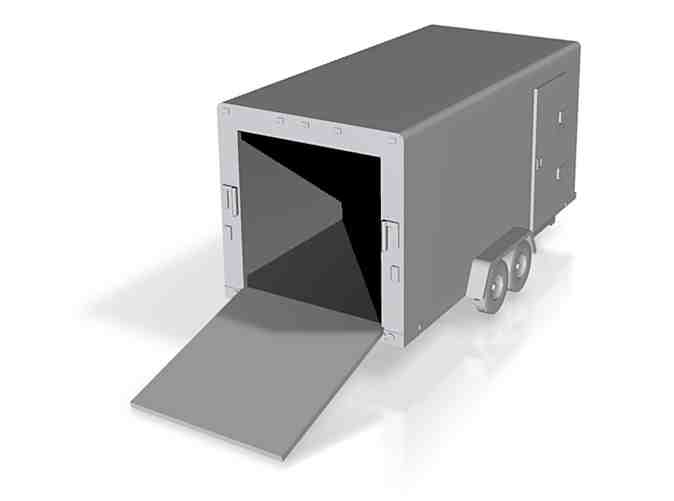

Cargo Trailer

Again, I was playing around and ended up with some trailer models. What is interesting (for a designer) is that each of these trailers starts on the frame, and the differnt pieces were added to it to make the different trailers. I have not test printed the car or cargo trailers yet, but I think they'll print OK.

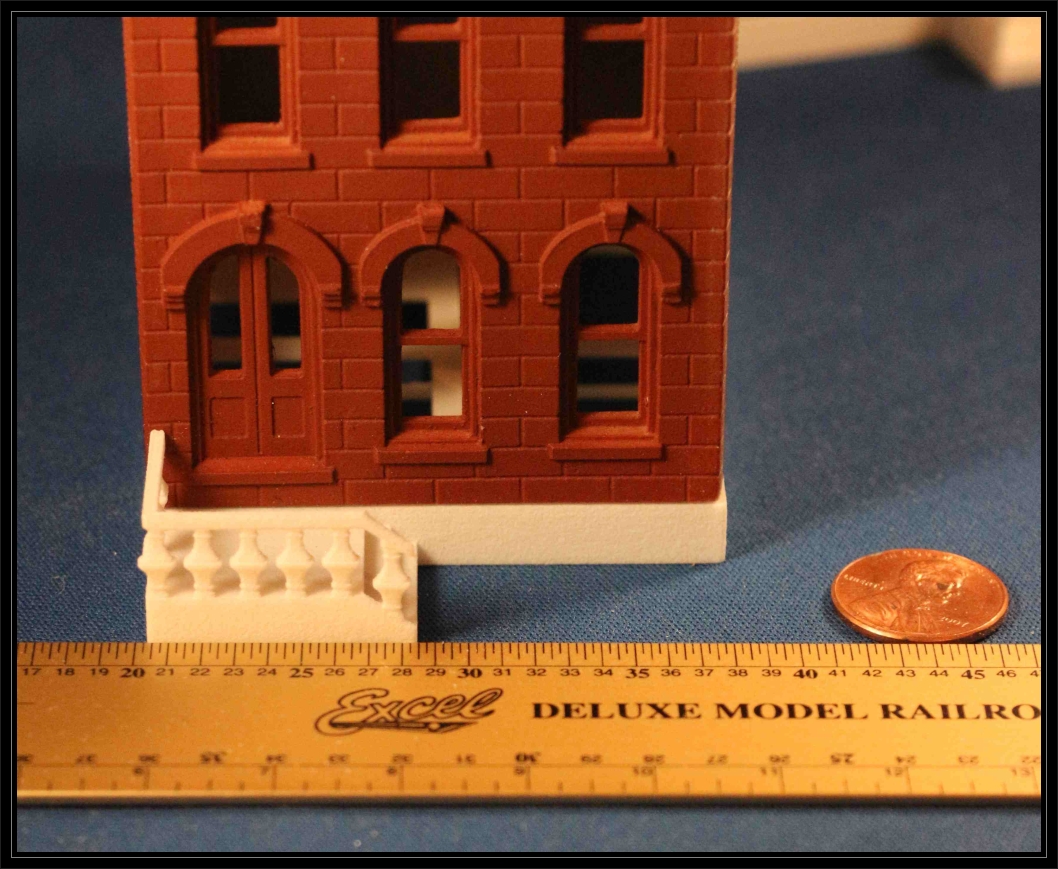

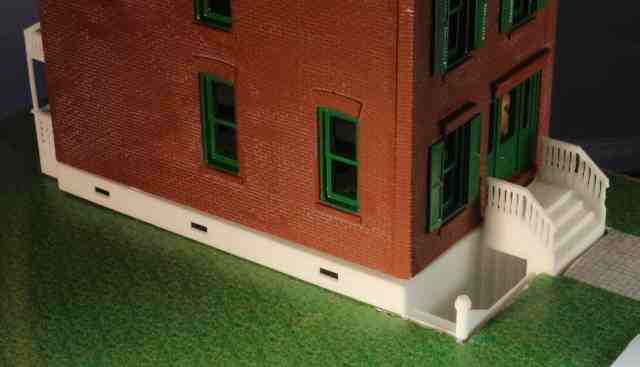

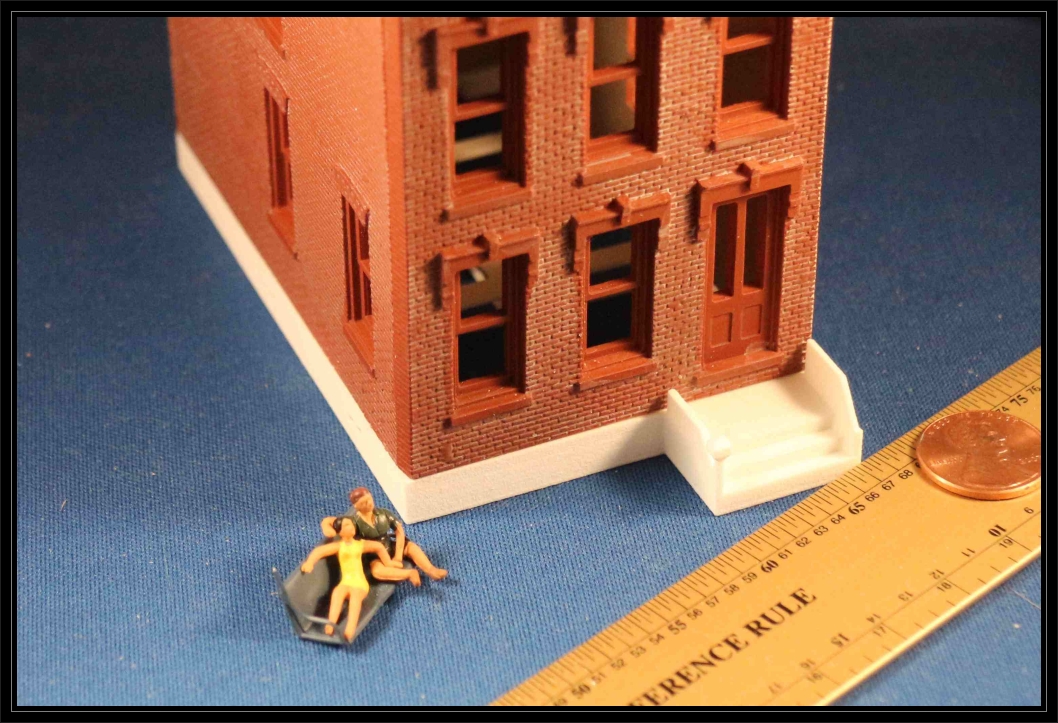

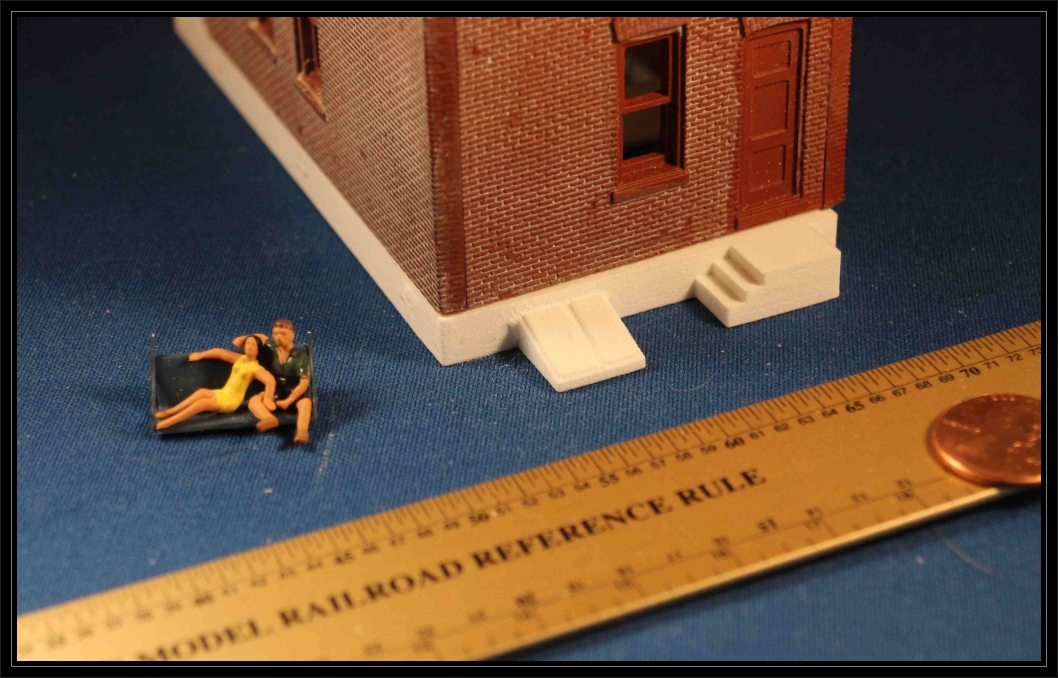

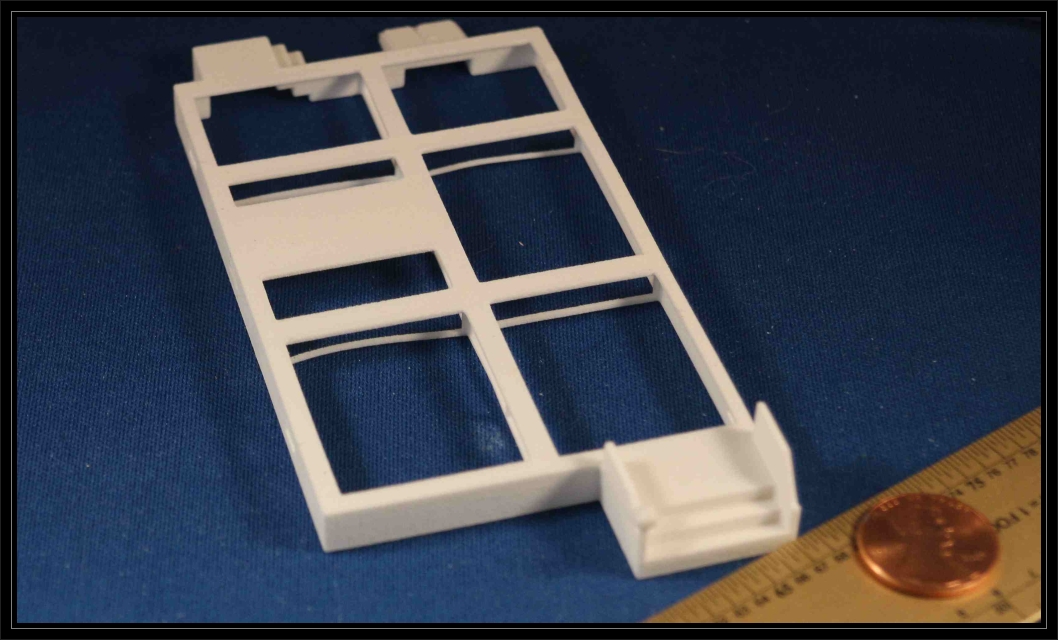

Details for Design Preservation Models buildings

I didn't like the look of these buildings flat on the layout, so I did foundations for them to sit on. A warning, none of my townhouses are the same width in the rear and the front. Some extra sanding is needed to make them square. Becasue the size of the footprint can vary depending on the amount of sanding you do, you may have a slight size difference.

DPM Townhouse Foudation- left door

DPM Townhouse Foundation- Right Door-Wide

I was going for a New York Brownstone effect with this one. It certainly adds some character to one of the most common kits in HO Scale. The rear porch roof did not print very well. I am not sure if it was a defective print or my design, but I fixed mine it by covering it with a thin piece of styrene.

DPM Townhouse Foundation- Right Door-narrow

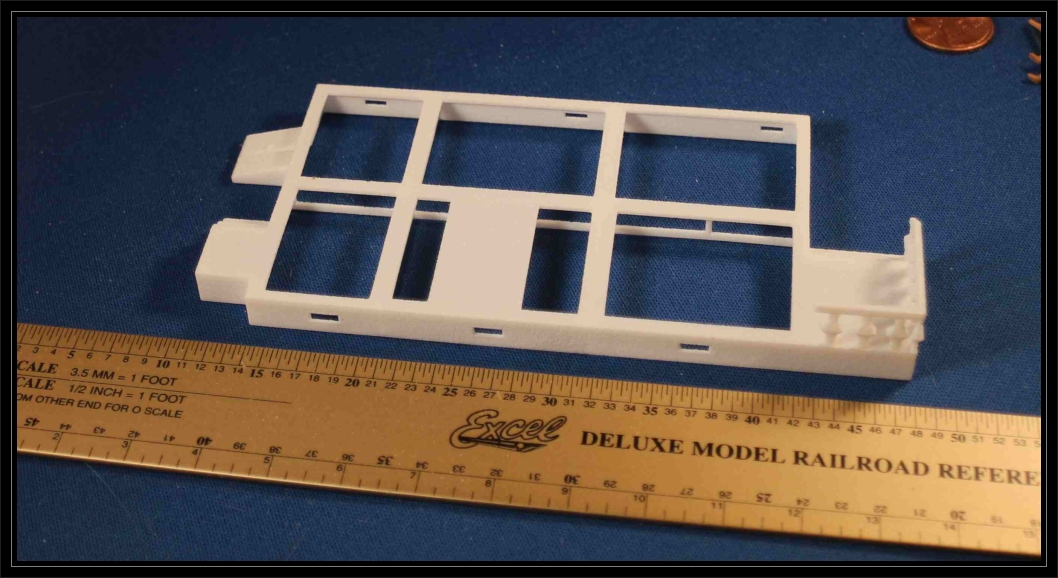

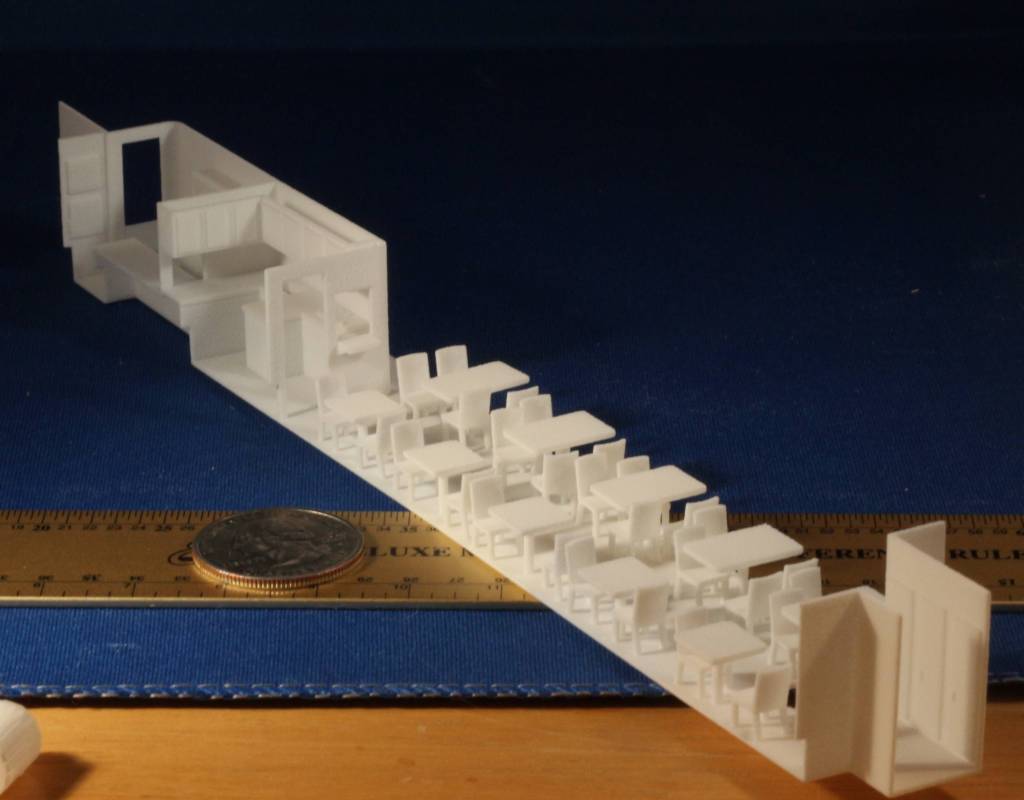

Interiors for Athearn Heavyweight Pullman Cars

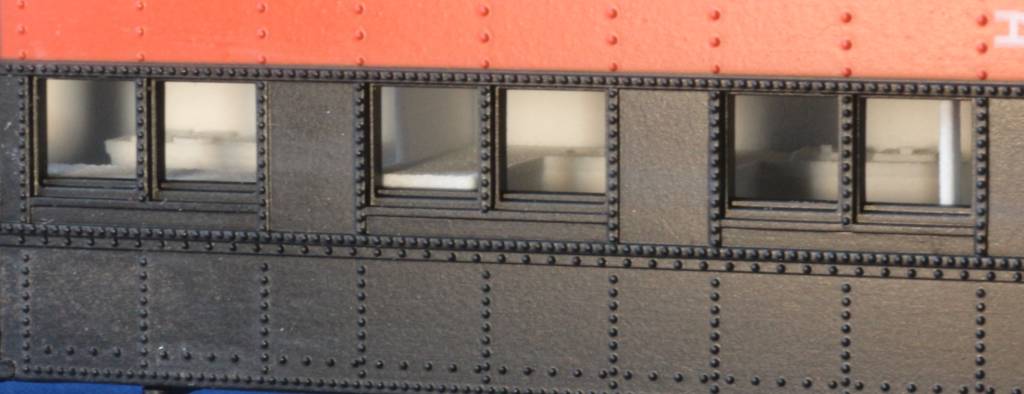

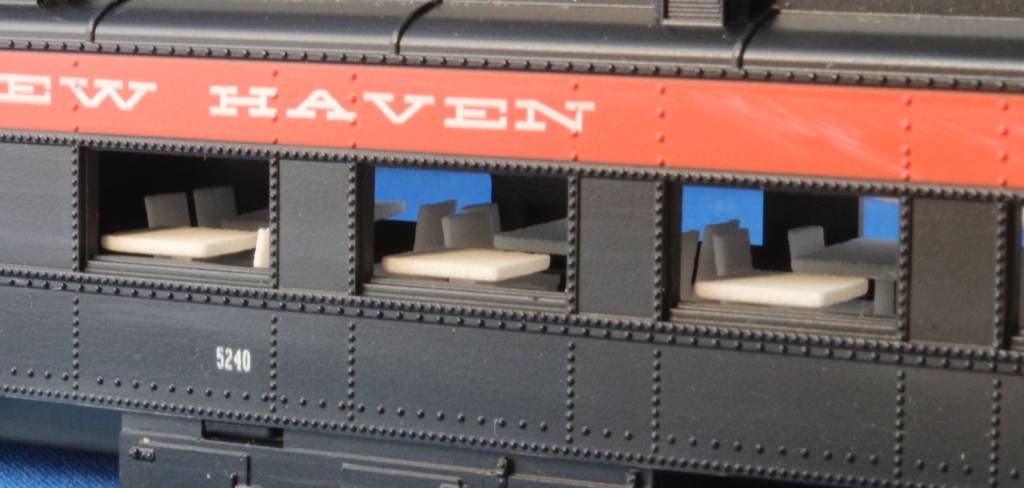

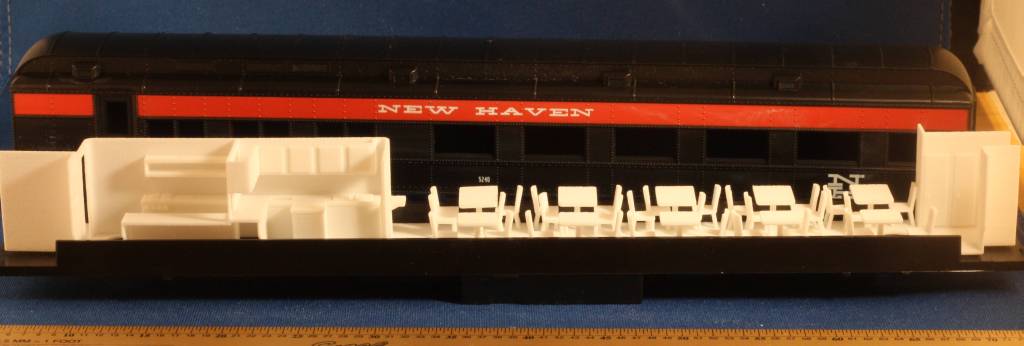

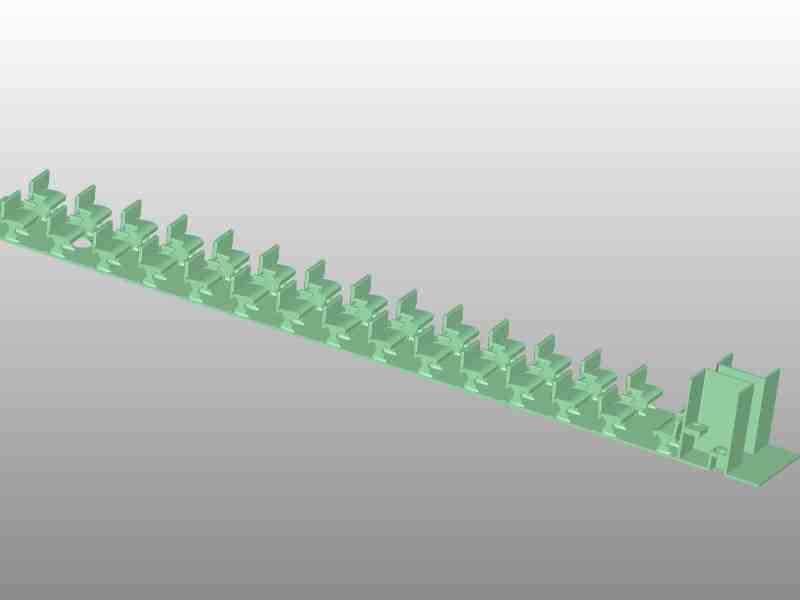

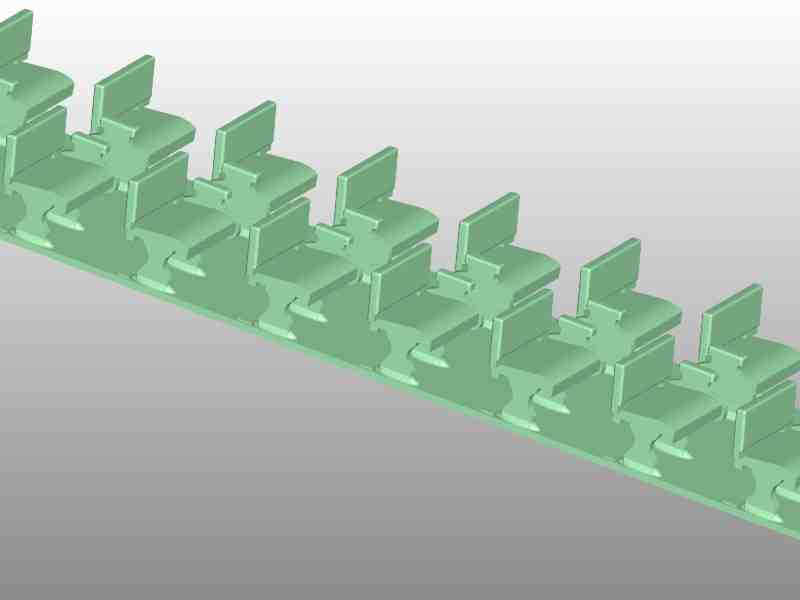

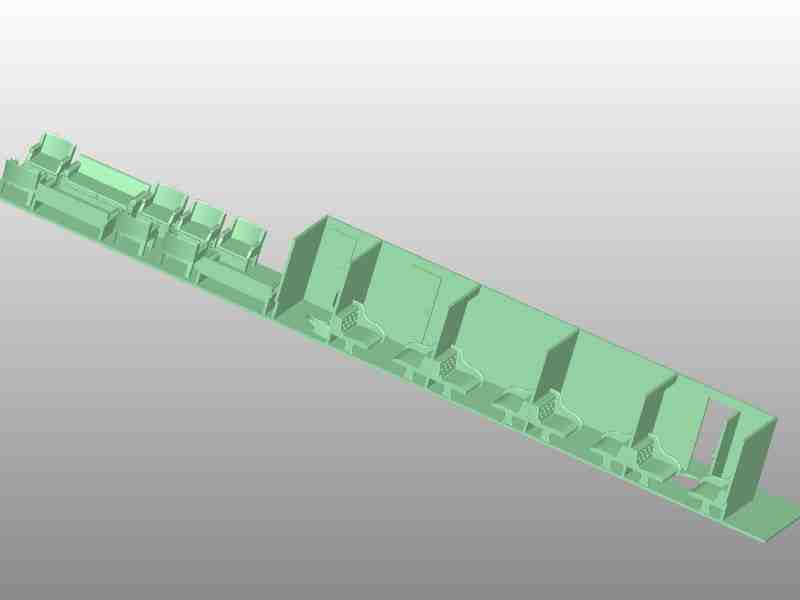

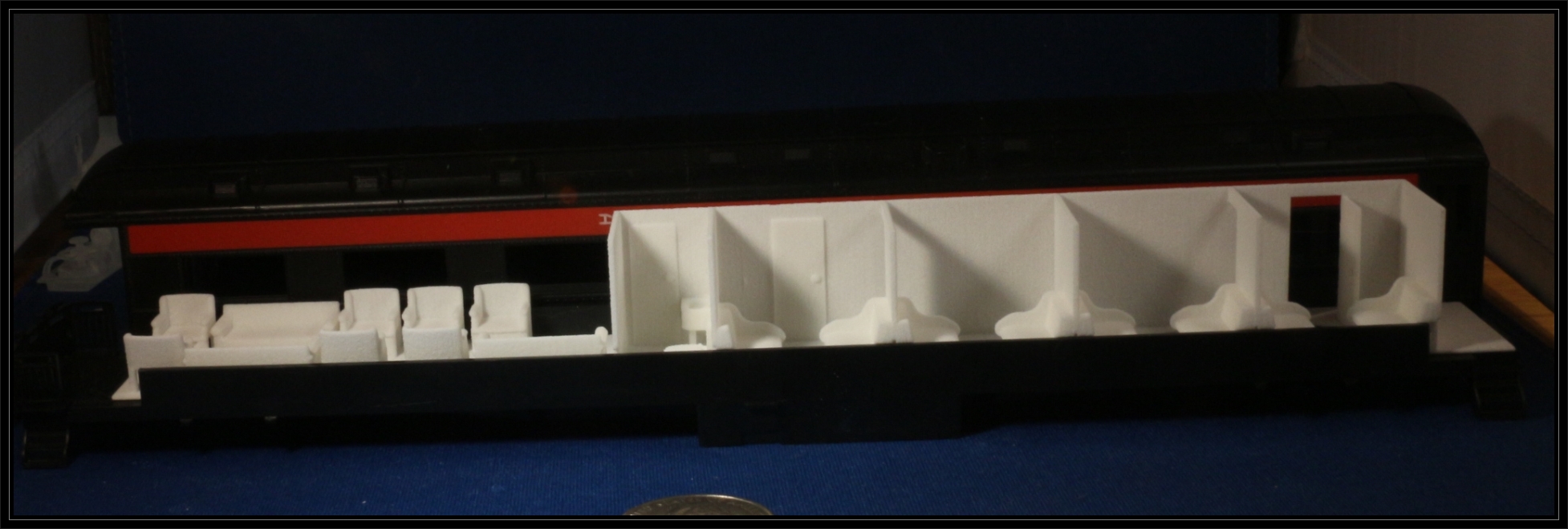

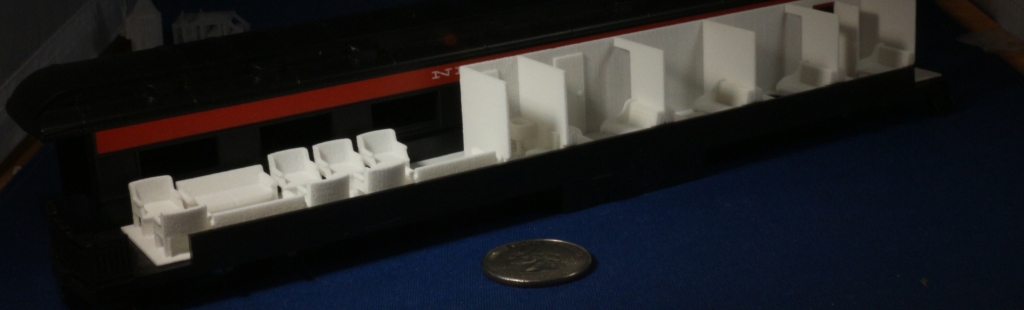

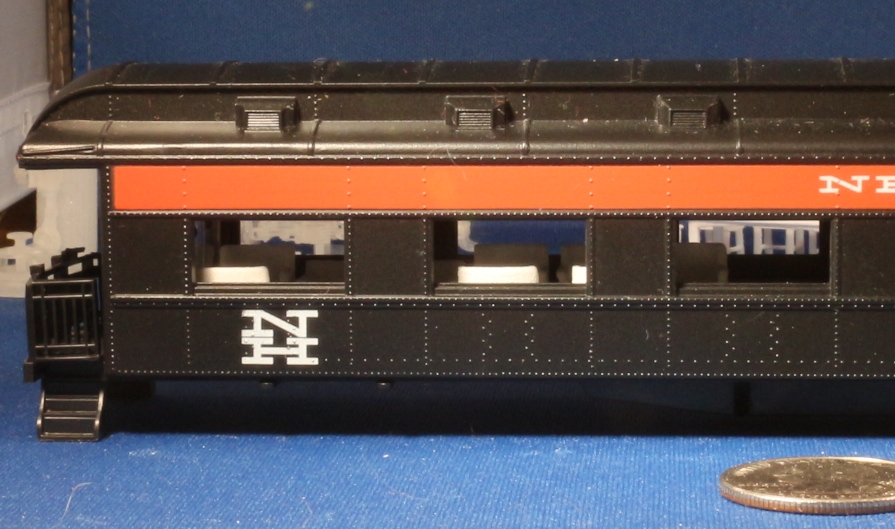

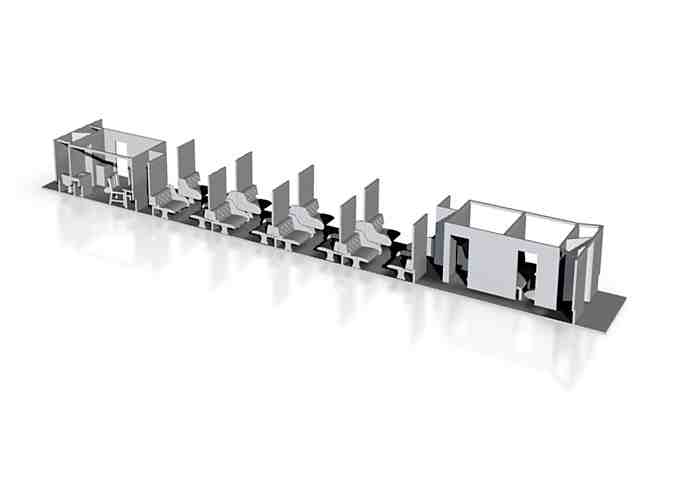

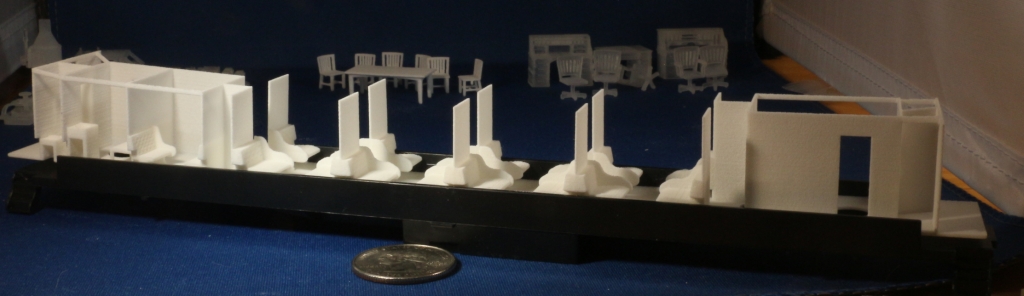

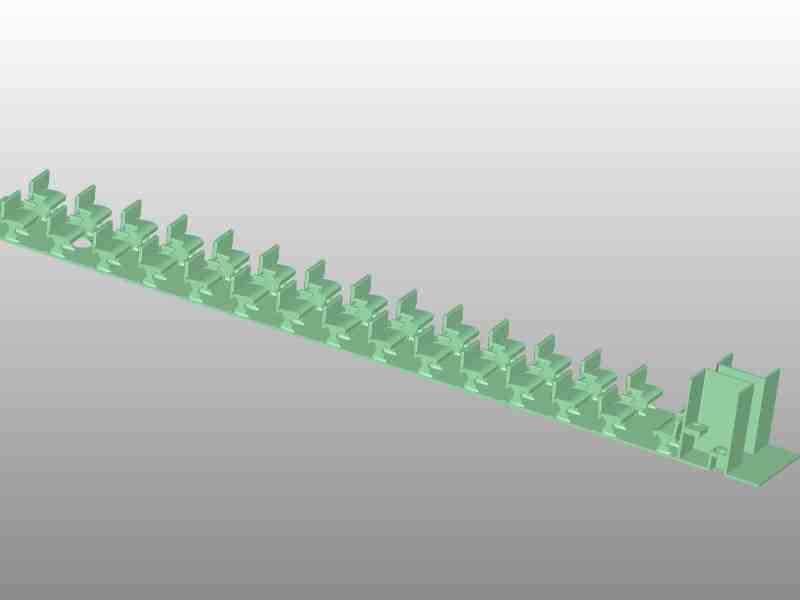

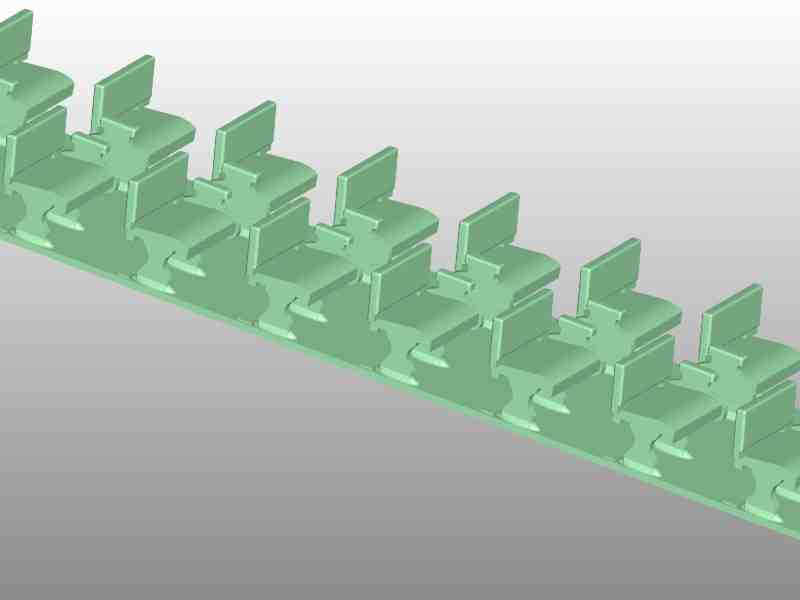

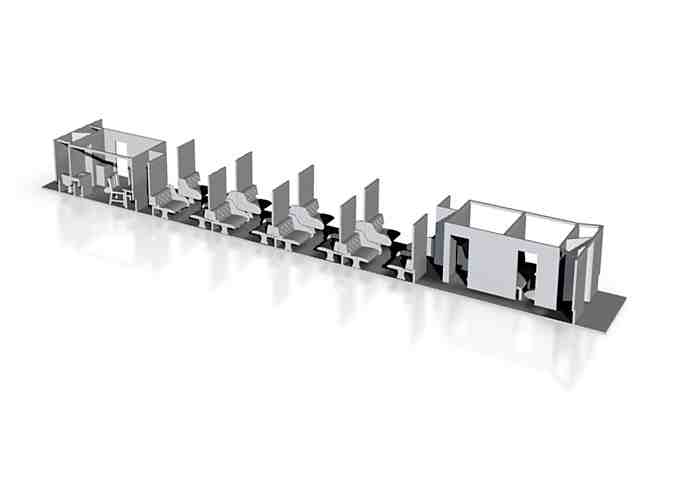

Go Back to TOPAs I write this, this is my latest project that I've gotten a test print back for, and I'm excited. Since I travel with my rolling stock to shows, durability is an issue. I have found out that delicate detail doesn't travel well. I got a good price on some Athearn hevyweight Pullman passenger cars that have a reputation for durability. I decided to try and make one piece interiors, and this is the result:

This design has not been test printed yet.

Athearn Observation Car Interior

Do you have a different brand passenger car you are interested in getting an interior for? Email me at dcyale@yahoo.com. We can work out something where you take careful measurements and pictures (or even scan the sides of the car on a flat bed scanner with a ruler) and I can work from your measurements. Email me first and we can set up the details.

S Scale Interior Details

I got a request for my woodworking machinery in S Scale. I did so, and understand the appeal of the scale. The details are much easier to see. It's not just a matter to making it bigger. Since the cost of the model depends partly on the amount of material, to keep costs down when a model is scaled up the walls need to be made thinner. When talking about bigger scales, although S may only be 25% bigger, the model grows in 3 dimensions, so the cost can double.

I intend to broaden my S Scale offerings. If you want a particualar item let me know.

S Scale Woodworking Tools without the workbench

S Scale Woodworking Tools with the workbench

The S Scale woodworking tools are available with and without the workbench. Also, some pictures do not show the table saw, which is part of the model. Blame the photographer. Also, the picture of the bench that look white is actually the HO version after a 20 minute soak in acetone.

Rectangular Table and 6 Chairs

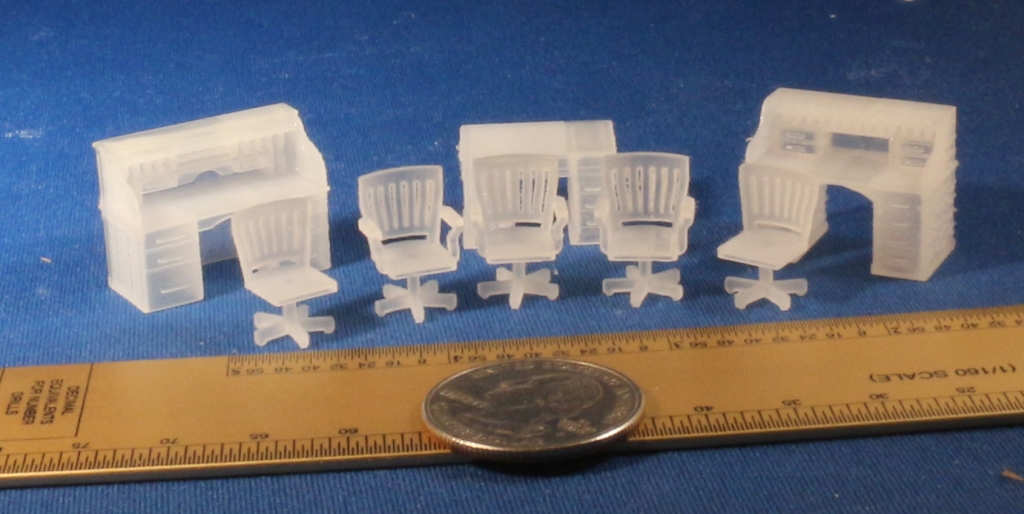

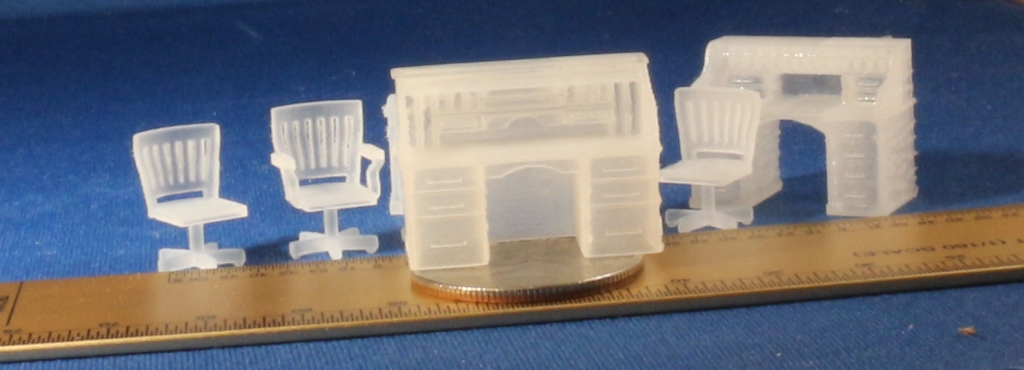

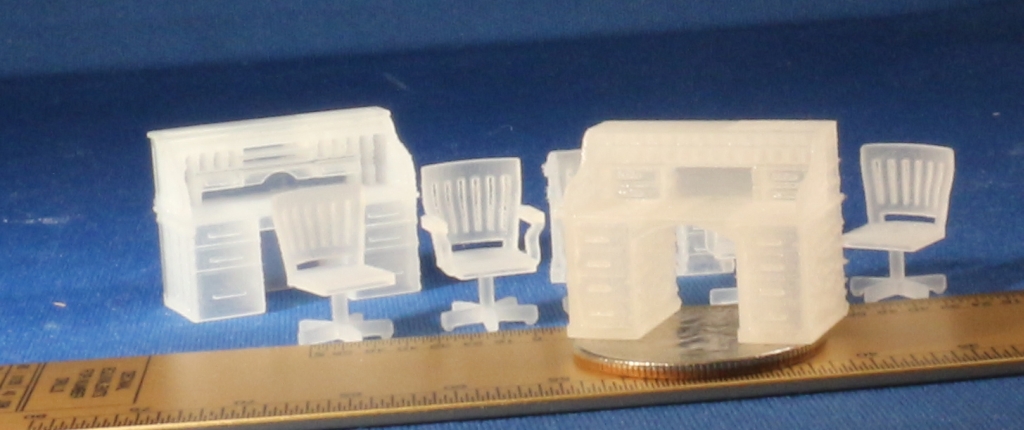

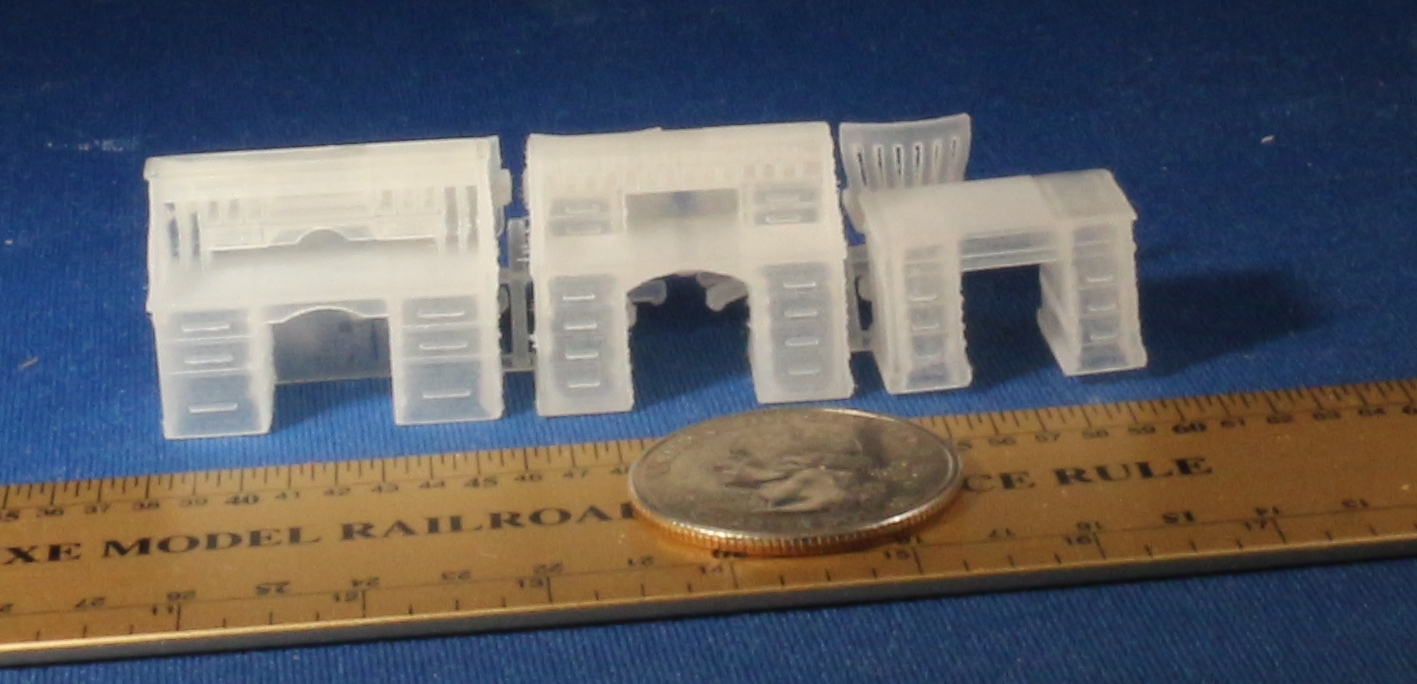

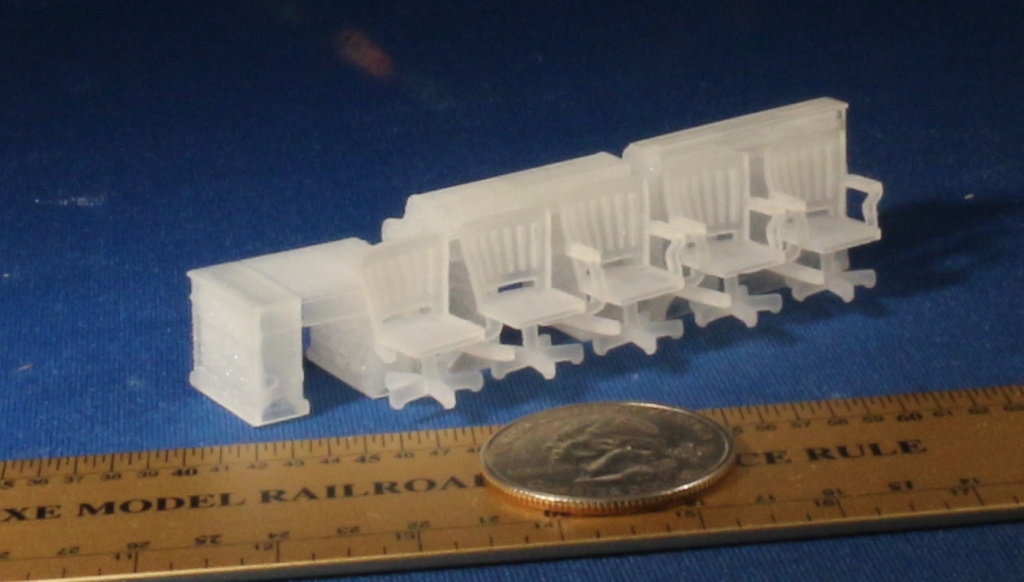

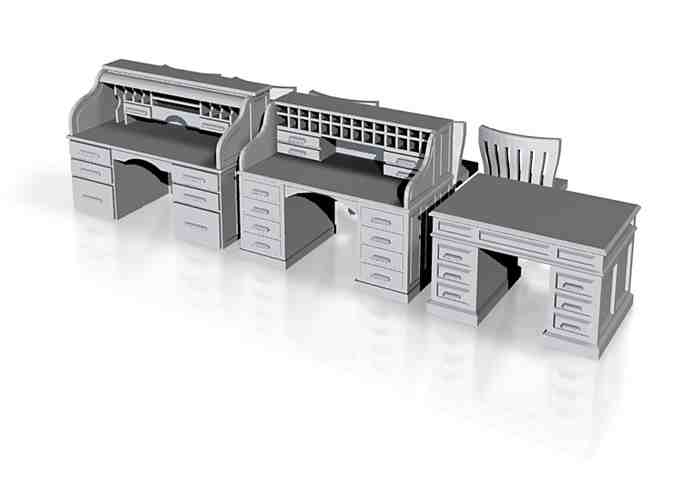

S Scale Rolltop Desks and Swivel Chairs

A set of two rolltop desks and one standard desk, along with 5 chairs. The FUD material doesn't photograph well, but this is model has great detail.

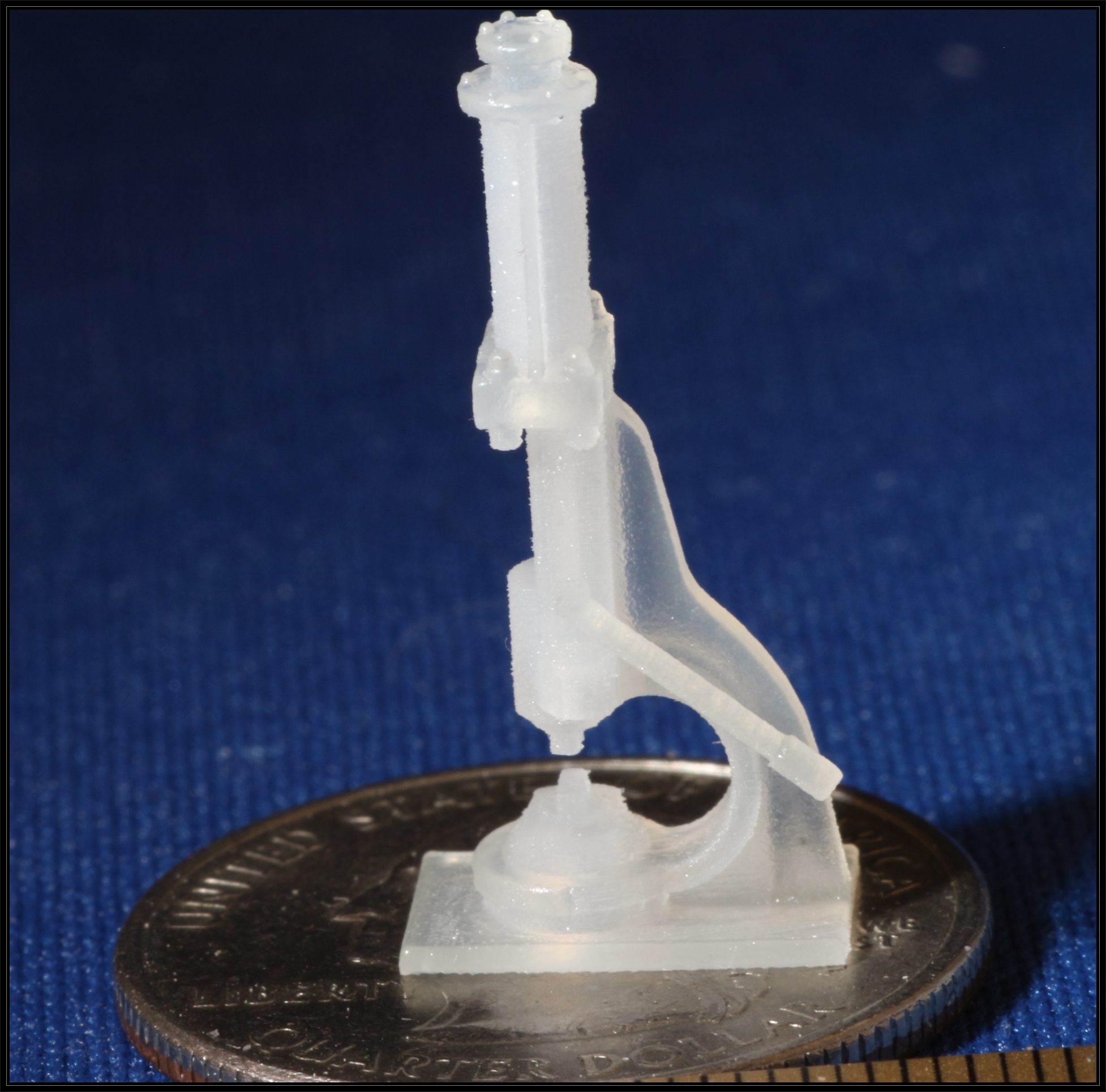

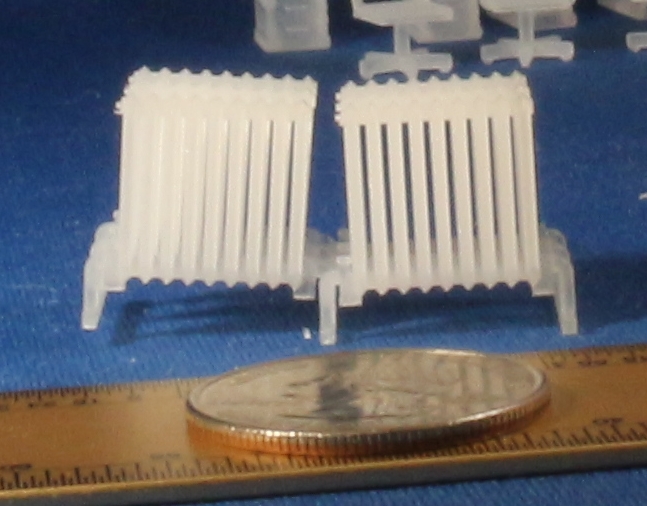

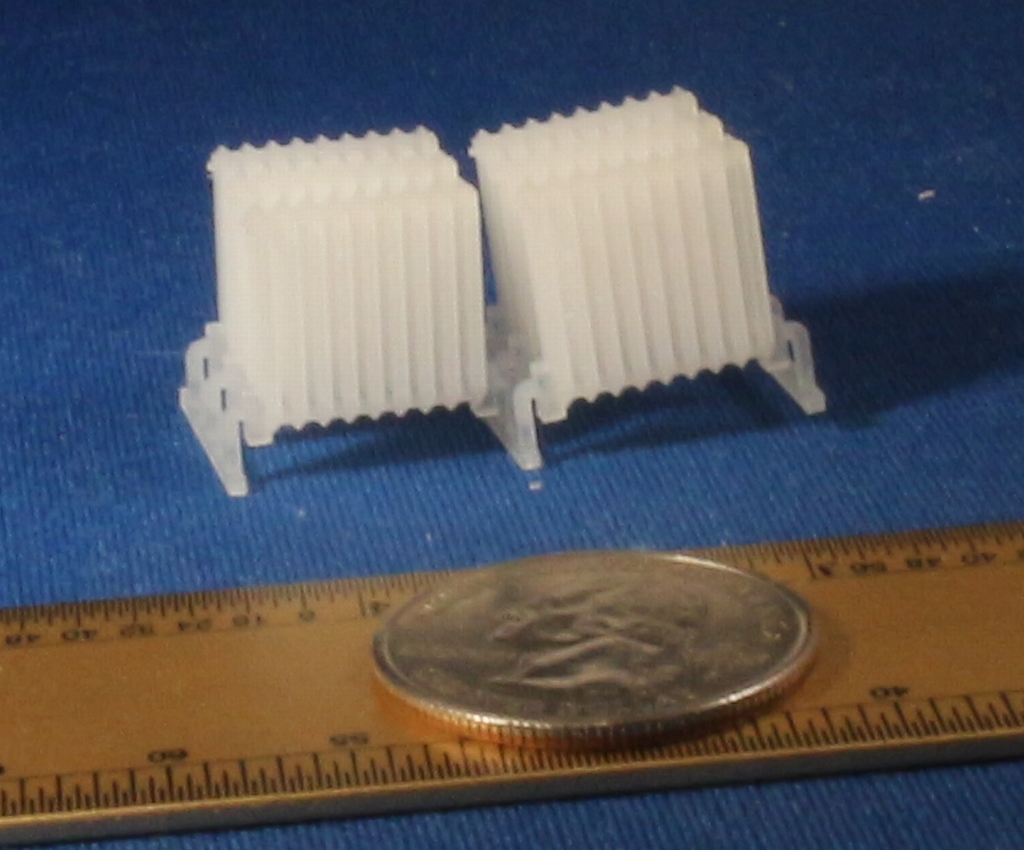

This is a set of 6 old style steam radiators. The pipes extend down so you can drill two small holes in the floor and mount the radiator with them.

S Scale Exterior Details

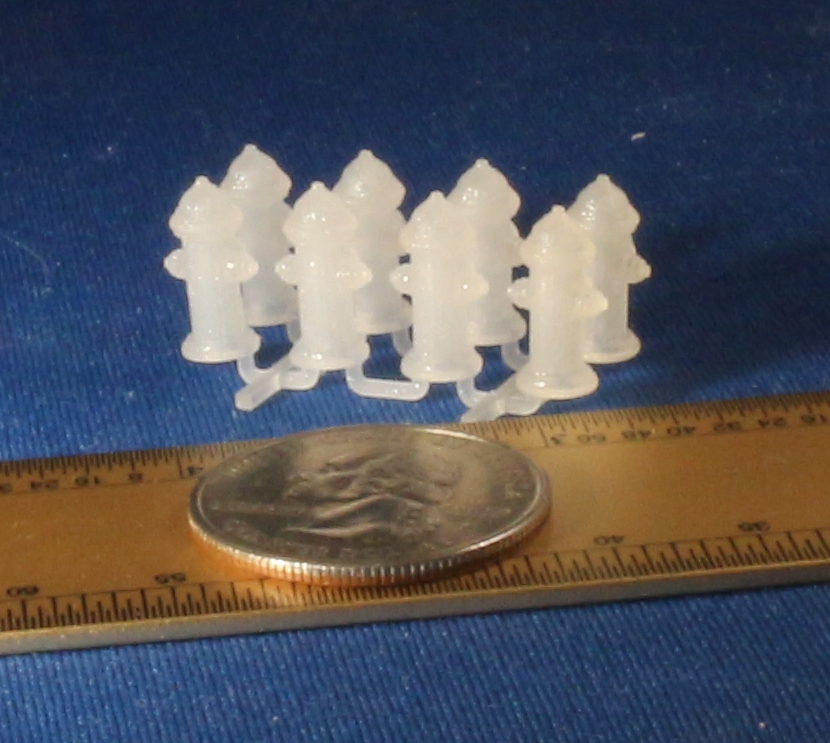

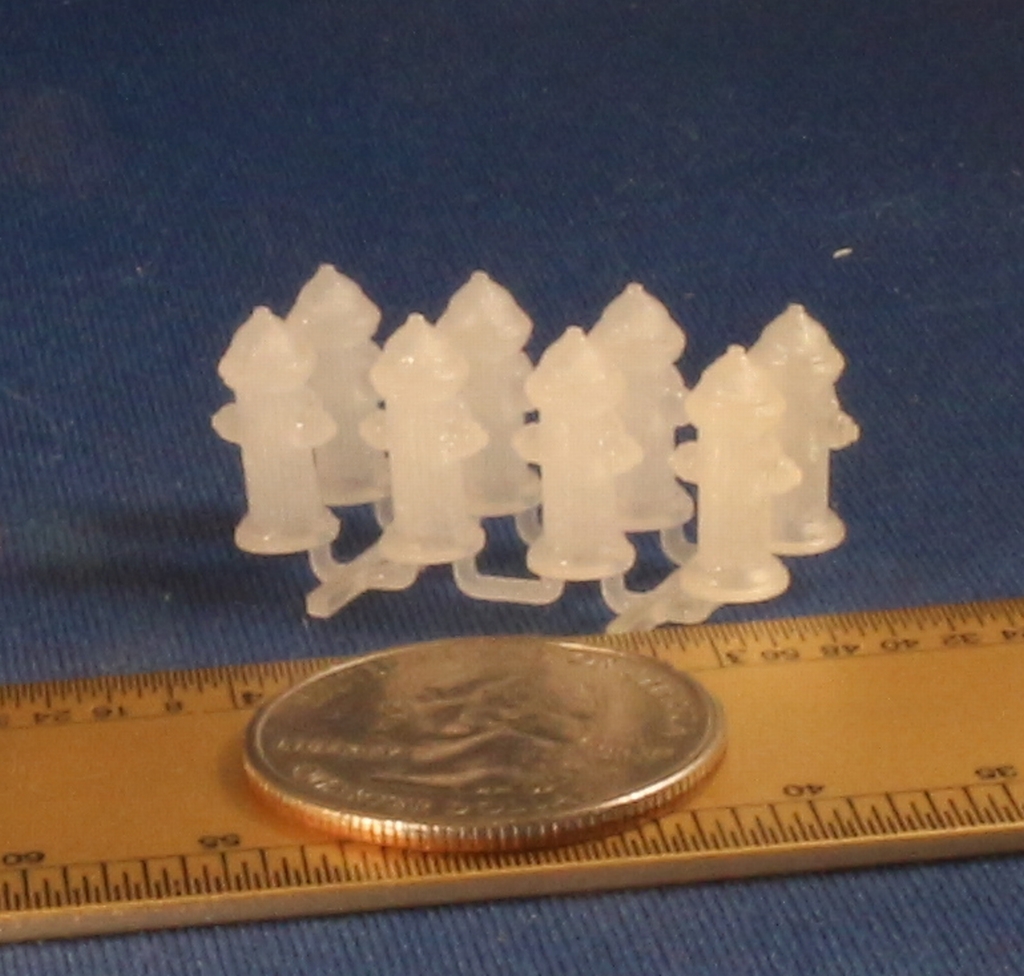

This is a set of 8 fire hydrants. The FUD material doesn't photograph well, but the detail is pretty good.

N Scale Details

Right now I have very limited offerings in N Scale. That will change, however. My future plans are to finish my HO module and then do an N-trak module. I already have a lot of N Scale items boxed up and I love the scale. When I get going I'm sure there will be things I want and can't get, so I'll make them.

This model has succesfully printed a couple of times for customers, but noone has sent me a photo of the completed model yet.

Future Projects and Works in Progress

One project I have been working on is an Elesco Water Heater for a New Haven Railroad Steam engine. I have a Bachman 4-8-2 that I picked up used and want to give it a New Haven Flavor, while not going crazy on trying to overdo it. Adding an elesco heater, and changing the headlight are probably the two things that will give me the biggest return.

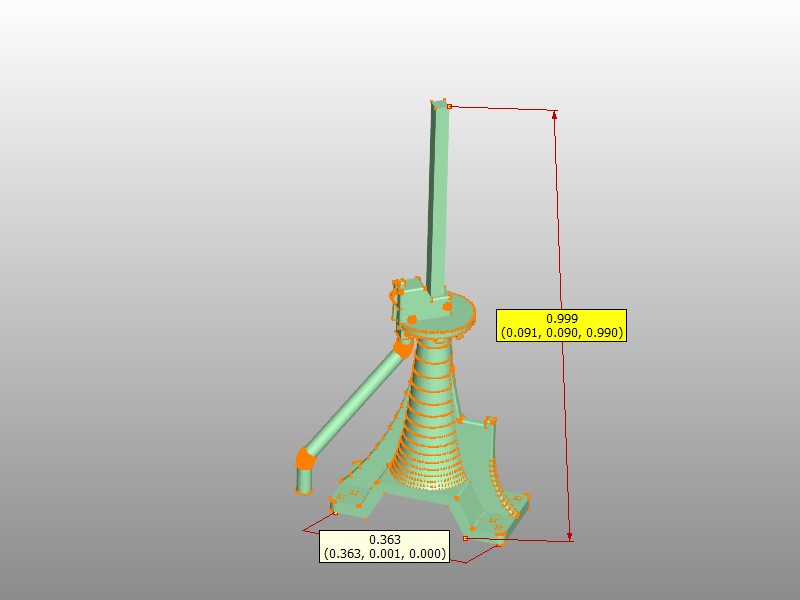

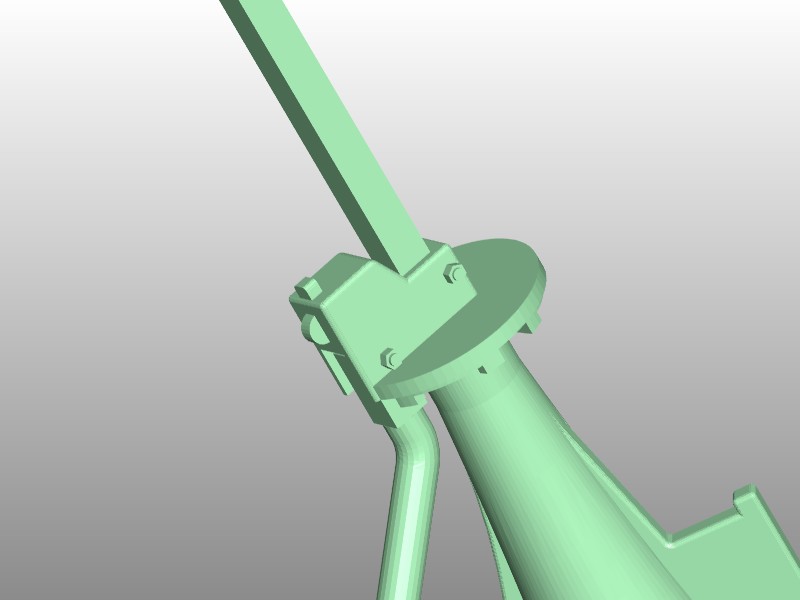

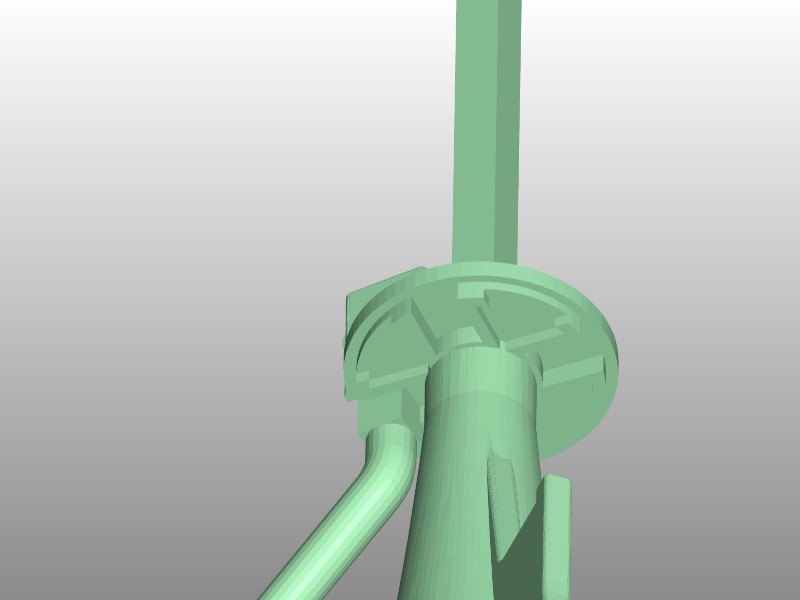

I found some pictures, and got some advice, and discovered the New Haven installed their Elecos different ways on different locomotives, and even used different models of heater. This is what I ended up with (so far):

Next is the piping that goes down to the steam pistons. I think the fresh water pipe will be done with brass wire. After that is the pump- which I will have to decide if I design or go with a commercial casting.

I also am working on a coach interior and a sleeping car interior for the Athrean Heavyweght Pullmans. The sleeper interior bothers me a little. The window spacing seems off and I had to make the compartments longer to fit, but when viewed through the windows I think it will be OK.

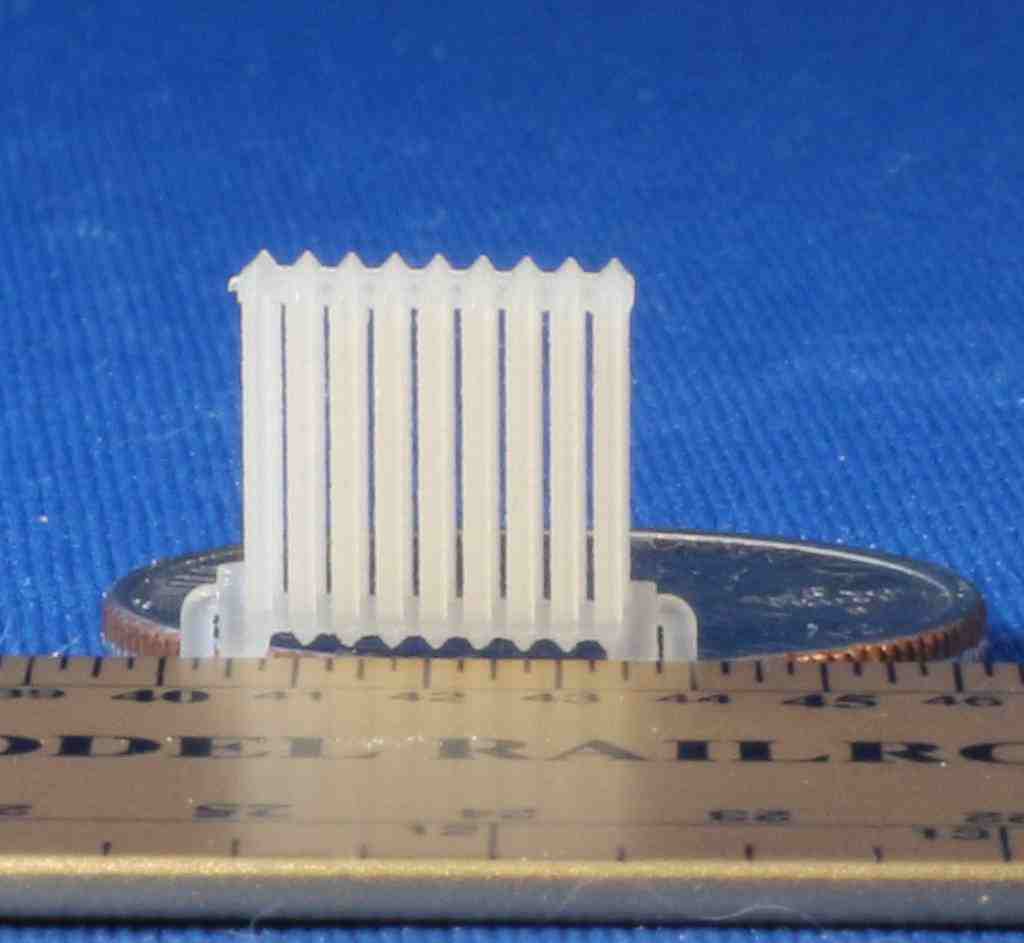

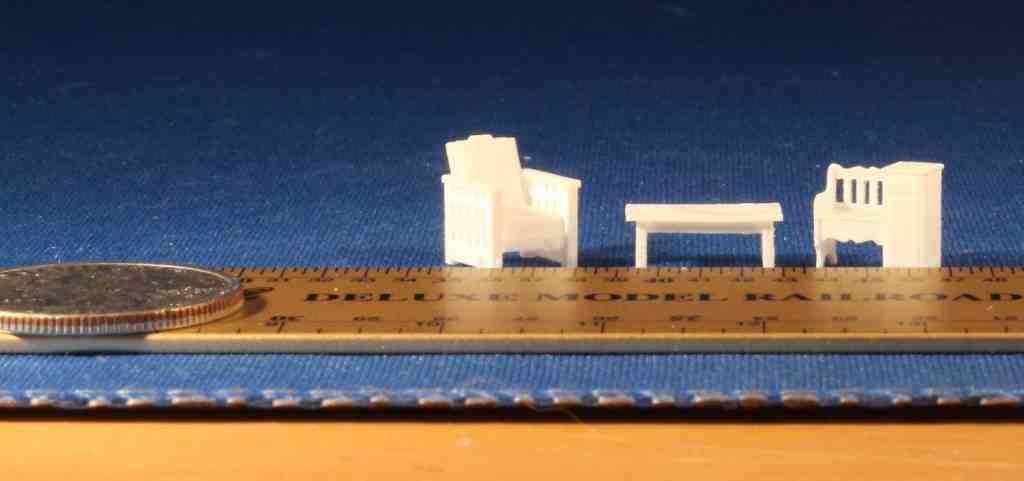

I am working on a new collection of furniture that I am going to call GRANDMAS HOUSE. It will have older style furniture and be done in ultra detail material. So far I have a Morris Chair, a Gossip Bench and a coffee table. The detail possible keeps amazing me:

I am also working on a switch stand used by the Canadian National Railroad in S Scale. Apparently the only company that made these went out of buisness.

I am not sure if I can go this in HO. The handle will be oversize becasue of the minimum size the technology can print. I won't know for sure until I try, but I think I will see how it comes out in O scale:

Cleaning, Painting and Finishing Models and Tutorials on 3D Design.

More inforation about painting models made from nylon material can be found HERE

Information about cleaning and painting Fine Ultra Detail items can be found HERE and HERE

Here is my tutorial on how to go from a color sketchup model to Shapeways by using Blender.

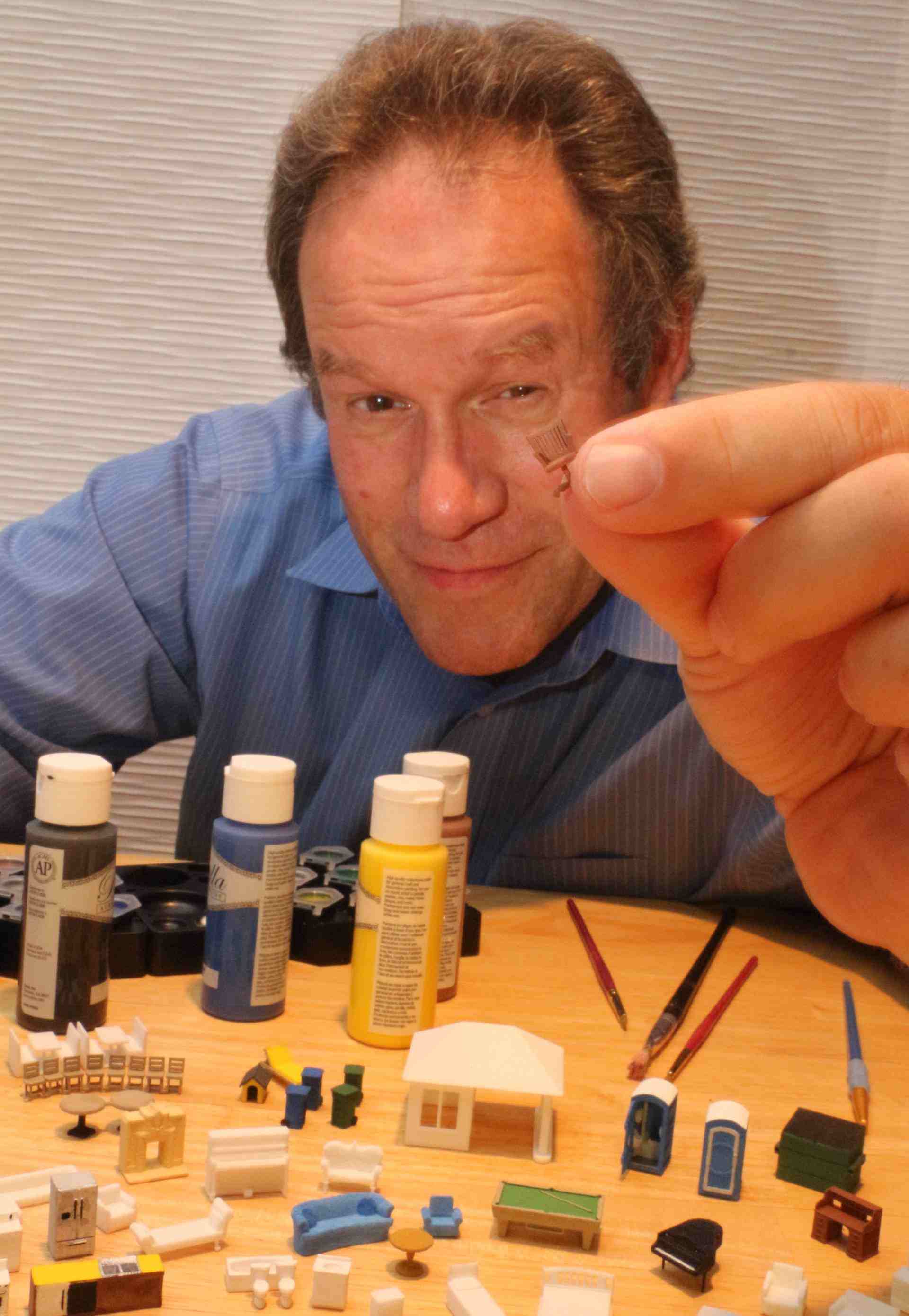

Go Back to TOPHow I Got In To 3D Printing

I decided I wanted some detail inside my buildings. My club models in HO scale, 1/87th life size. I looked around and found there are some really nice cast metal details, but the cost is very high. There is also a little bit of doll house furniture, but the size isn't really right. So I kept looking.

Eventually I hit upon 3d printing. I was looking on a site called Shapeways, and I saw some really nicely done N scale (1/160 life size) passenger cars from the post civil war time frame. The designs can be found HERE.. I also saw THIS ONE and THIS ONE. I decided if they could do it. maybe I could, too.

I started with the tutorials on the Shapeways site, and began using the free version of Sketchup. I added on a number of free plug ins that have been developed for it. Sketchup is fast to learn and fairly intuitive. It has some frustrating points, though, and doesn't do everything well. Still, I find it is my program of choice for now. A search on youtube will give you a bunch of videos that demonstrate the program better than I can.

After I am done with Sketchup, I use NetFabb and A free 3d viewer to review my 3d cad file. If I did my design lifesize, like a piece of furniture, I scale it down in and center it is Meshlab. I'd be lying if I said I understood why it has to be centered- I just know I have to do it.

On some models I load it into Blender, another free 3d cad program. I use about 5% of blender's power at this point. There are two major things I use blender for right now. If I am going to print a model that is 8 different pieces of furniture, each started as seperate design. I import them into blender one at a time, and then connect them with sprues (although I am told the correct term is "runners." The other thing I use blender for is to create arrays. If I am putting together a porch railing and it will have 20 posts which are all identical, with Blender I can import one post, then tell Blender to repeat if 19 more times and adjust the spacing so they are correct in the model. It's a lot easier than trying to line up 20 post by eye.

The learning curve is kind of steep at first, but you get the hang of it. Go Back to TOP

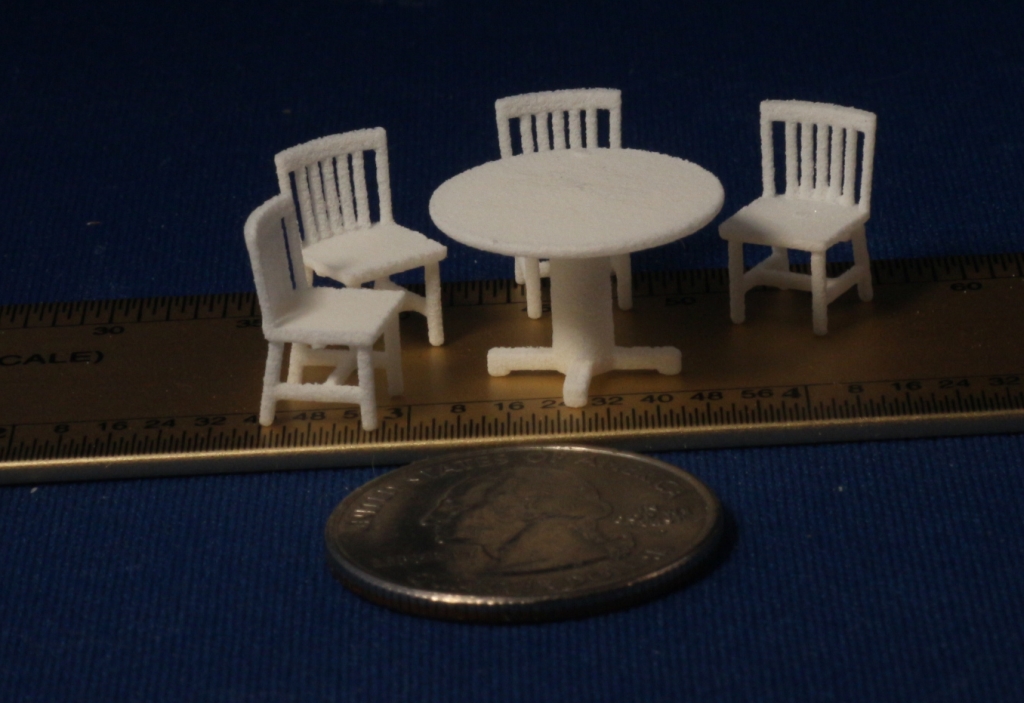

The first model I did was a simple chair:

I wanted interior details for a restaurant and so I designed a set of tables and chairs. I looked at many, many models of each to see what different people had done and how they had designed them.

Eventually I added booths:

Bedroom Furniture:

Kitchen and Bath Fixtures:

Living Room furniture:

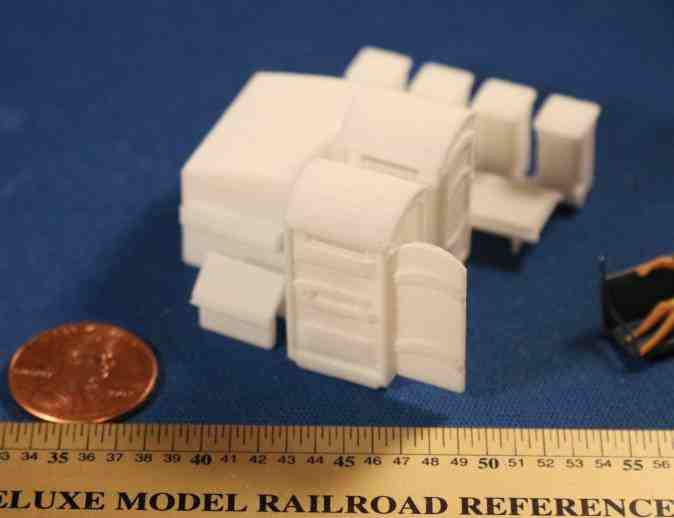

Some outside details:

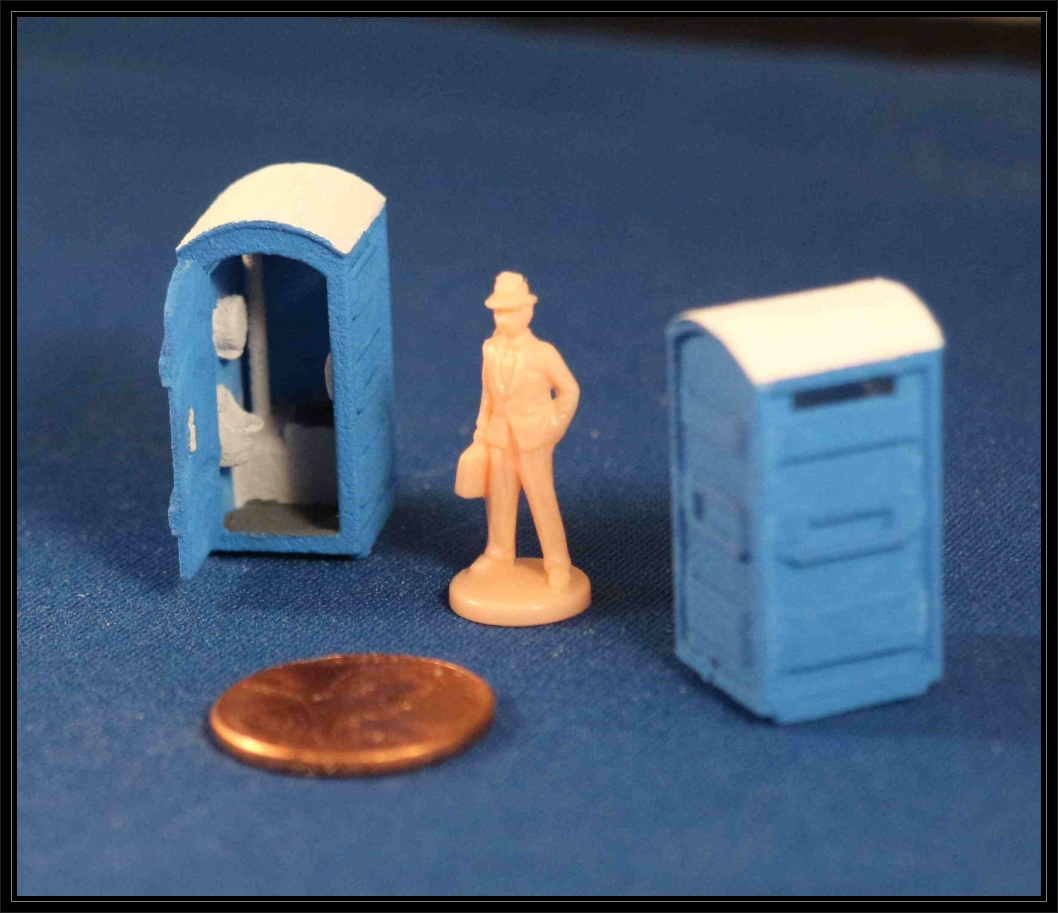

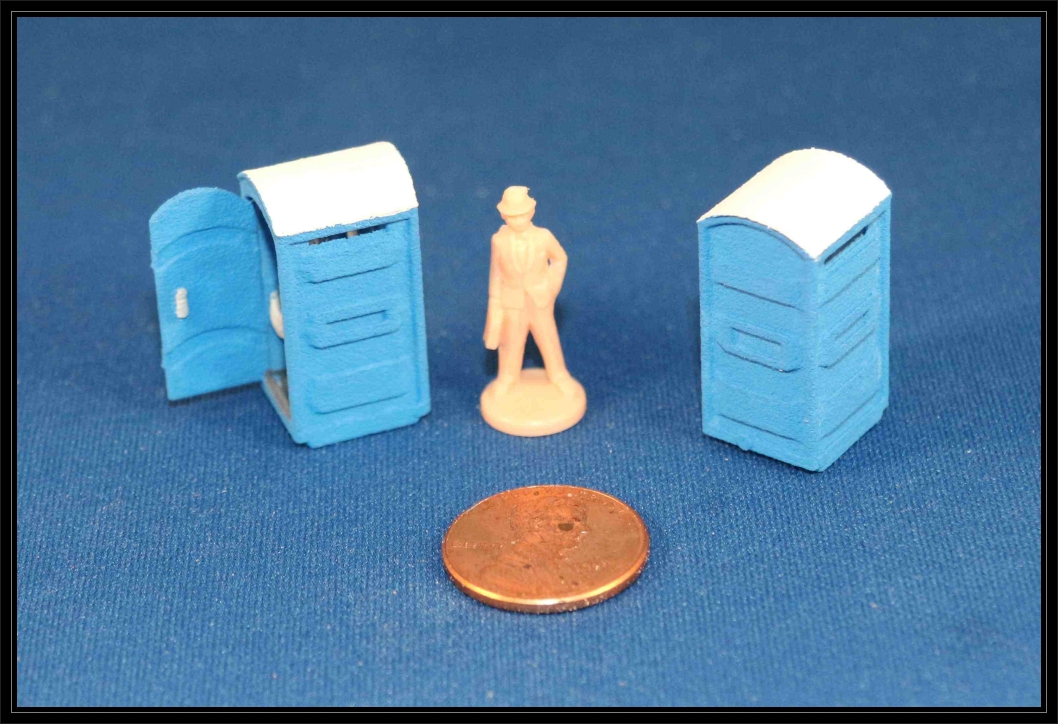

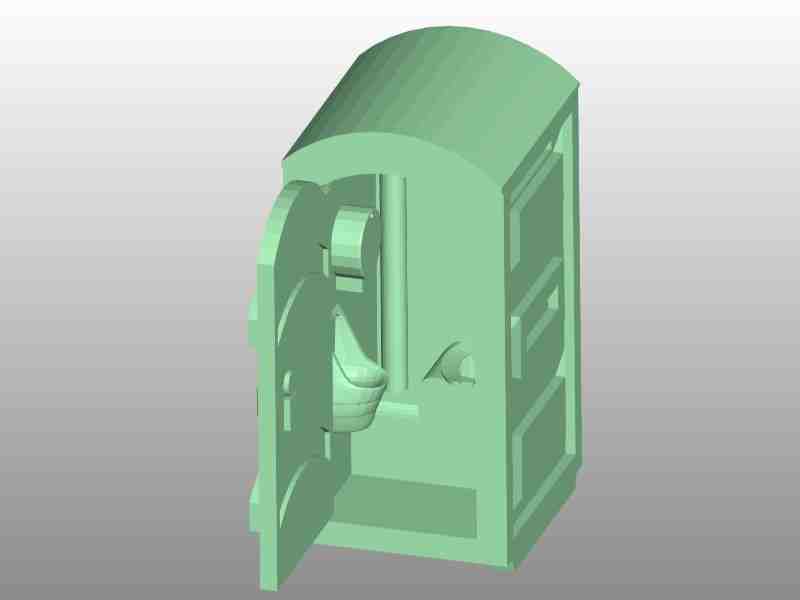

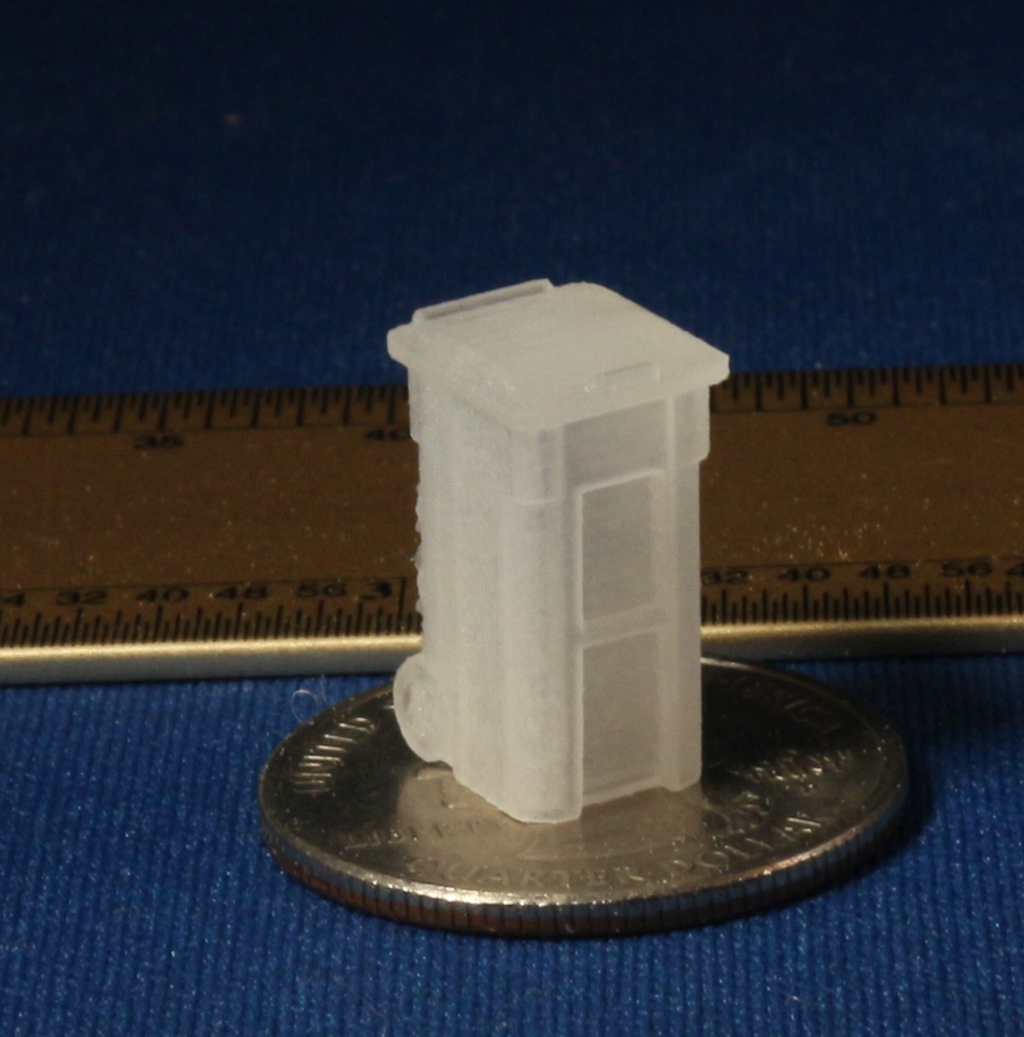

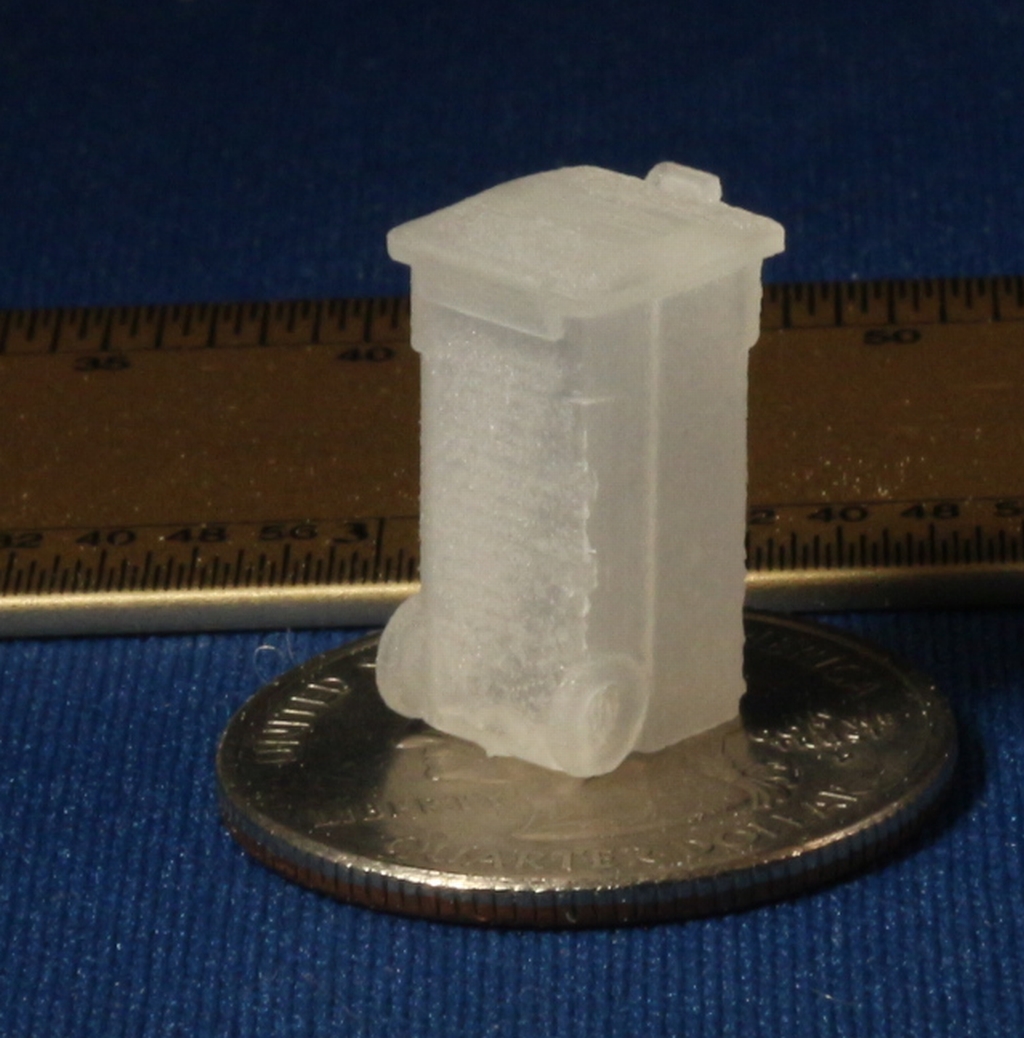

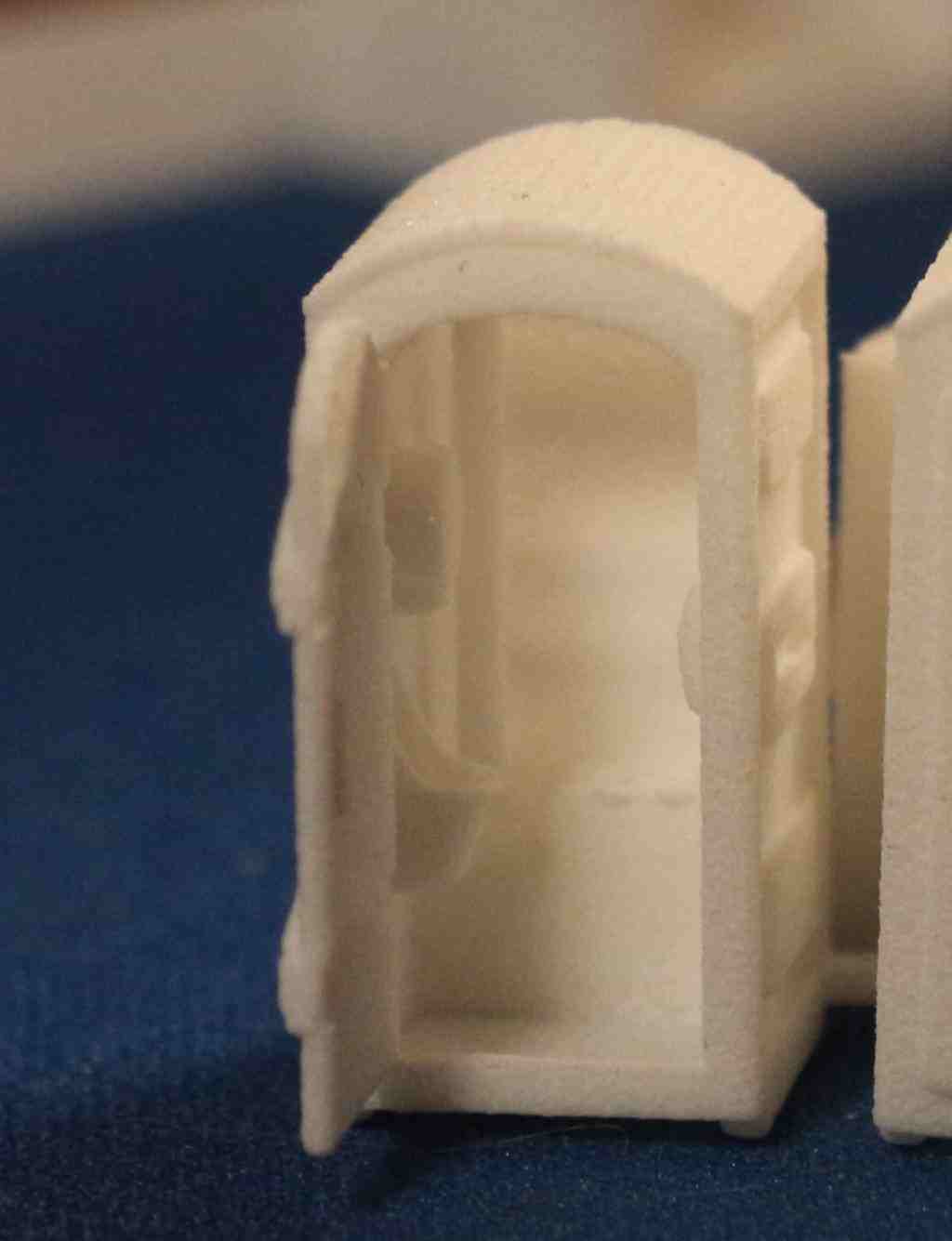

And even a fully interior detailed port-a-pot:

This concrete bridge support was printed in full color- what you see is how it was delivered.

I also tried a foundation for a building. One of my street will have a steep grade and every building needs a custom foundation. Some I made from styrene, some I printed.

HOW GOOD IS 3D PRINTING?

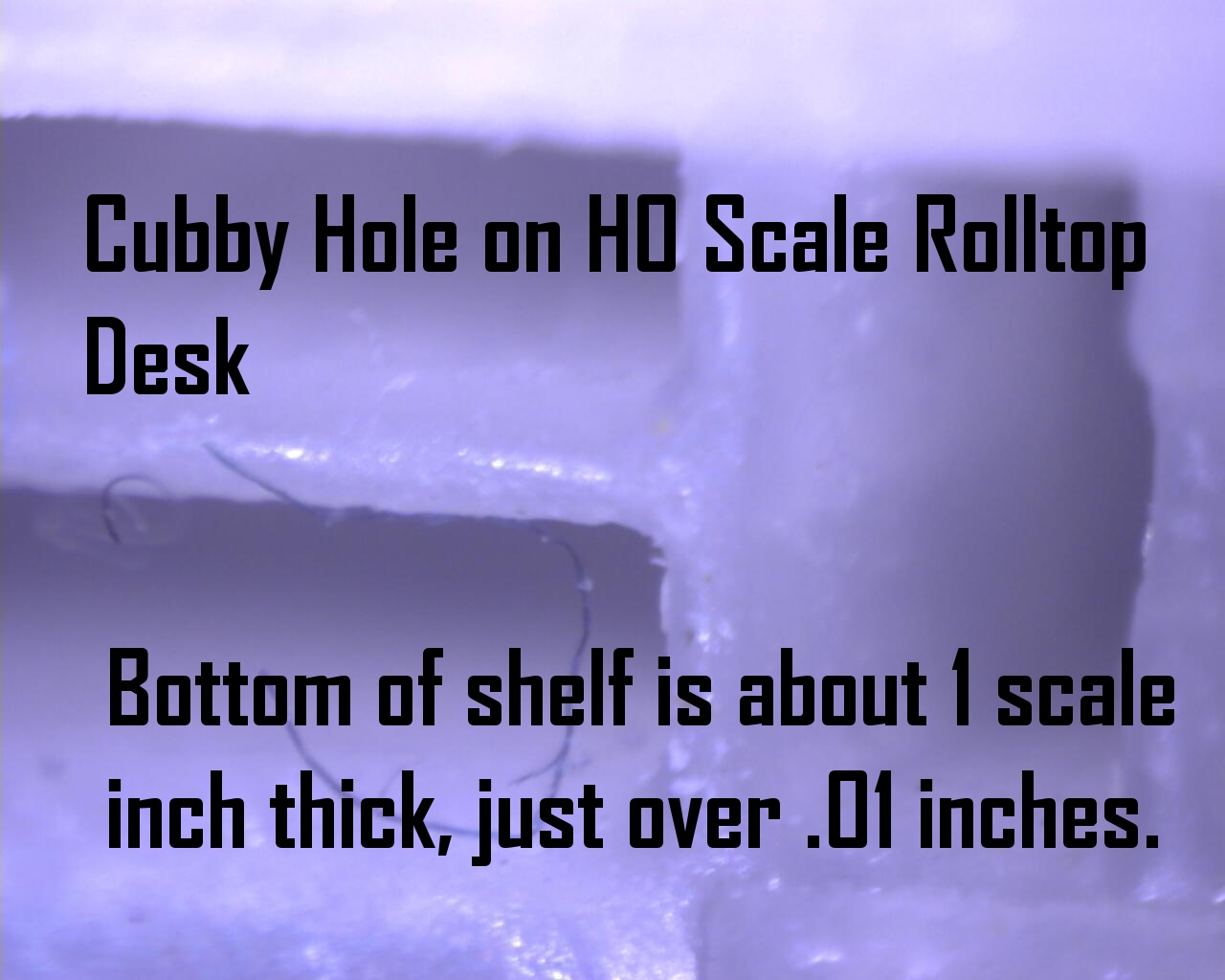

Almost all of my models are made from one of two different materials. The high detail material is called "Frosted Ultra Detail", or "FUD." This material starts as liquid resin and is cured into the shape of the model by UV light. FUD can go down to a wall about 1 inch thick in HO Scale, or about 3/4 of an inch in S Scale. This material is more exepensive, and needs to be cleaned before painting. I use a 20 minute soak in Acetone, but there are a lot of warnings about acetone. Some people have reported good success with white vinegar. I usually run the models I sell direct and off ebay through a white vinegar and water bath in an untrasonic cleaner before I ship them. You can pick out FUD models by the translucent look to them- the woodworking machinery for instance.

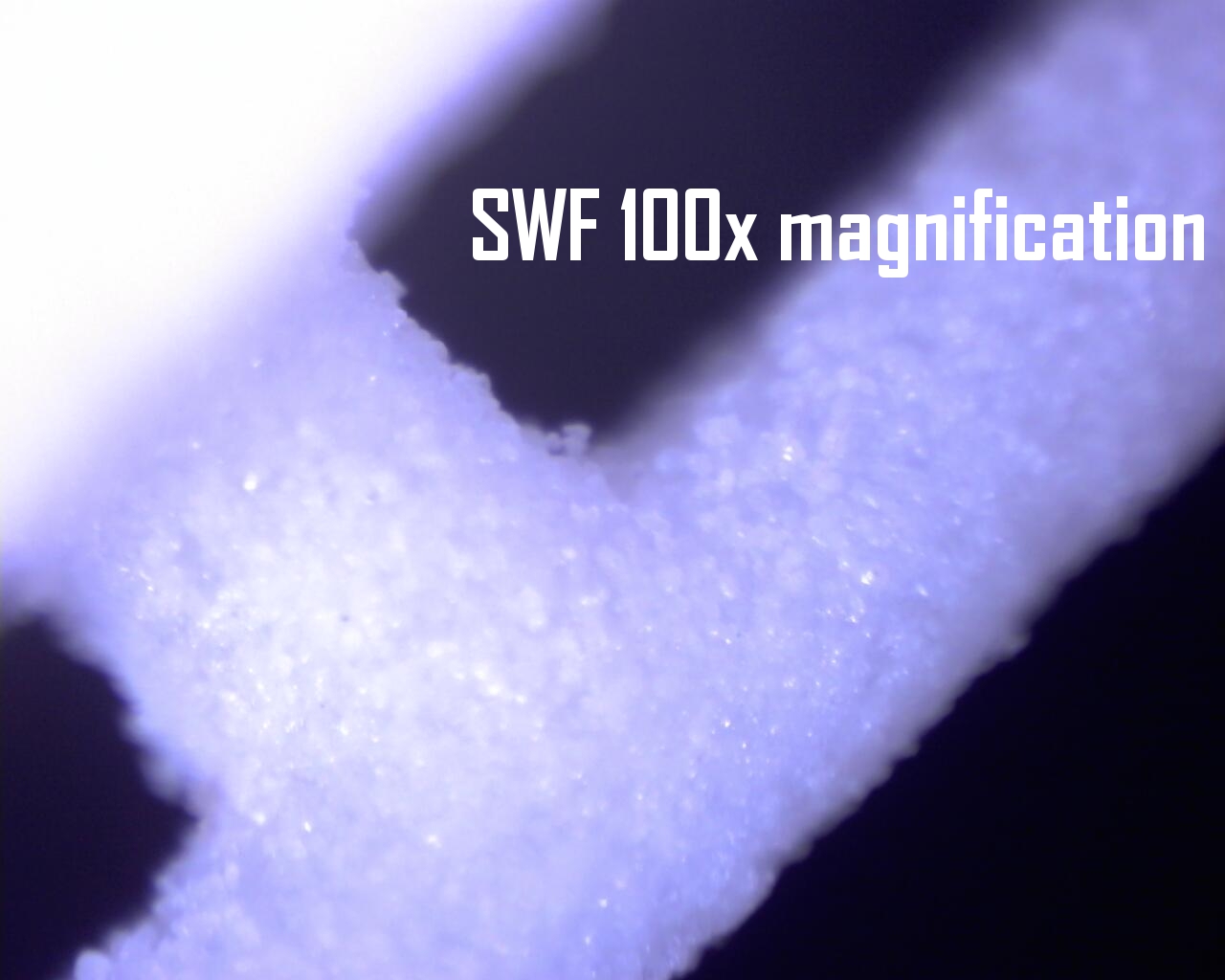

The other common material is "White Strong and Flexible" or "WSF." It is a nylon material that is fused with a laser, layer by layer. It has a slightly rough appearance, although it shows up more in photographs than it does to the naked eye. Nevertheless, on a detail that is right at the edge of the layout it may be noticable. On the other hand, WSF is quite a bit less expensive than FUD. One model I designed in WSF, then redesigned in FUD, was twice as expensive in FUD for a model that basically looked the same, but with a rougher appearance in WSF. So for details that are going to be seen thorough windows, or are not going to be seen to closely, I use SWF. SWF is also less brittle than FUD.

For the best appearance, and the abiilty to model finer details, I use FUD. Otherwise I use WSF. More informtion about painting and cleaning these material is located farther down on the page, below the models.

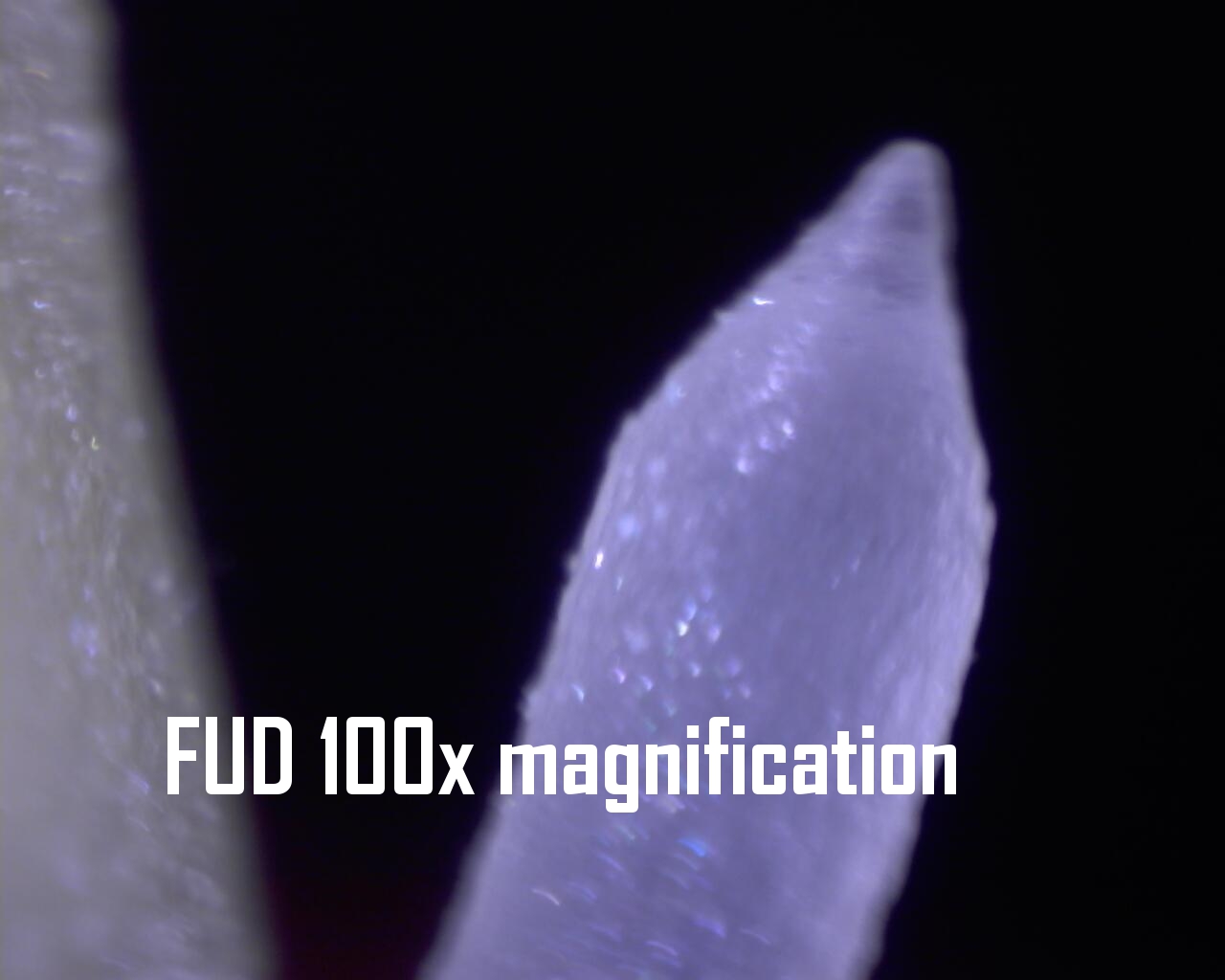

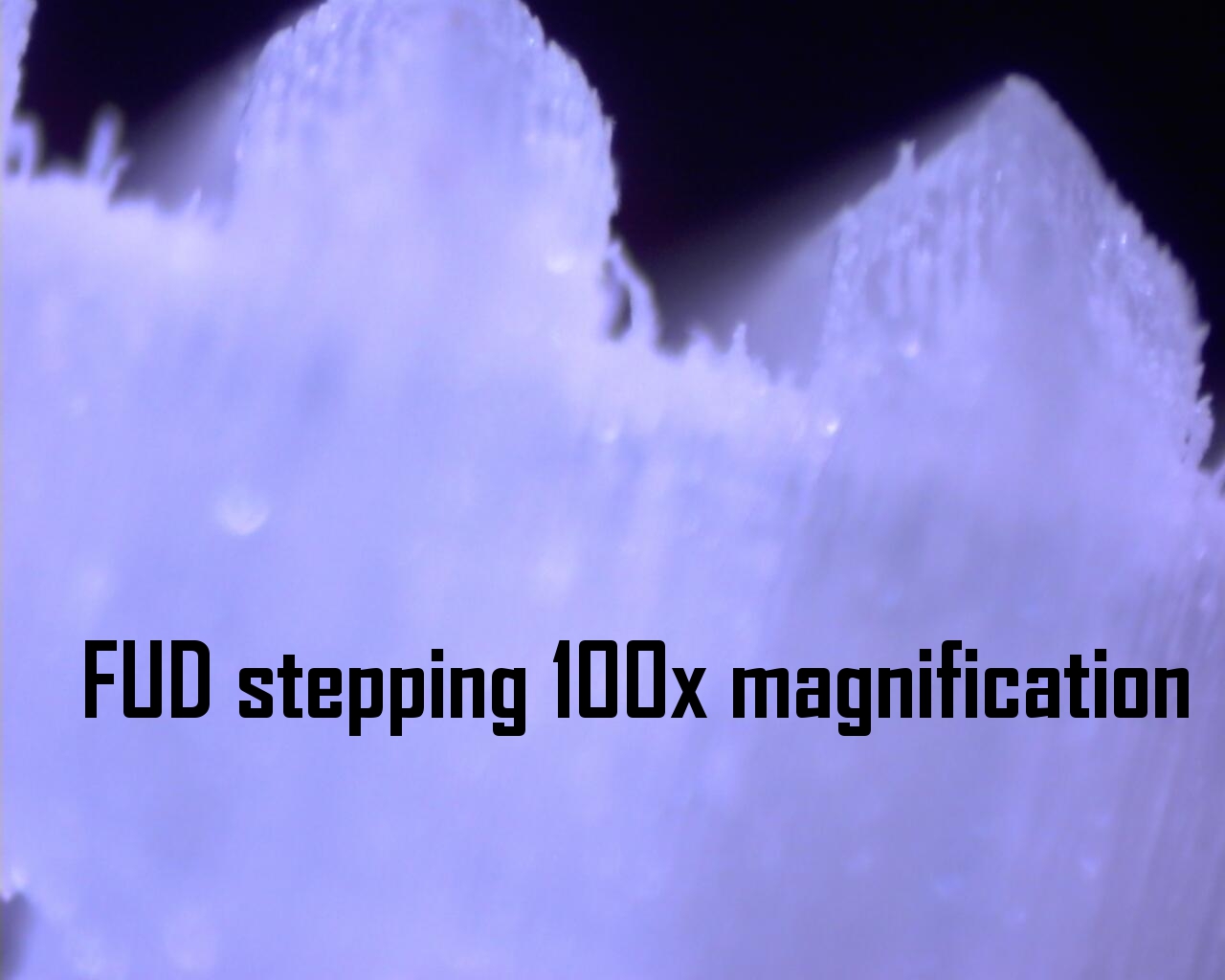

Recently my teenage daughter found an inexpensive microscopic camera she got years ago called a "Bionic Eye." I grabbed it to take some pictures of 3D printed models:

The camera calims it is 100x magnification. As a bench mark here is the "L" from Liberty on a US Quarter:

The low resolution SWF is made of obvious nylon particles. Ity is easy to see why paint can bleed though, and why it has a slightly rough appearance.

Here is a close up of the mail cubby on an HO Scale rolltop desk. There is a thread in the photo that I still can't see with the naked eye. I think this is pretty good.

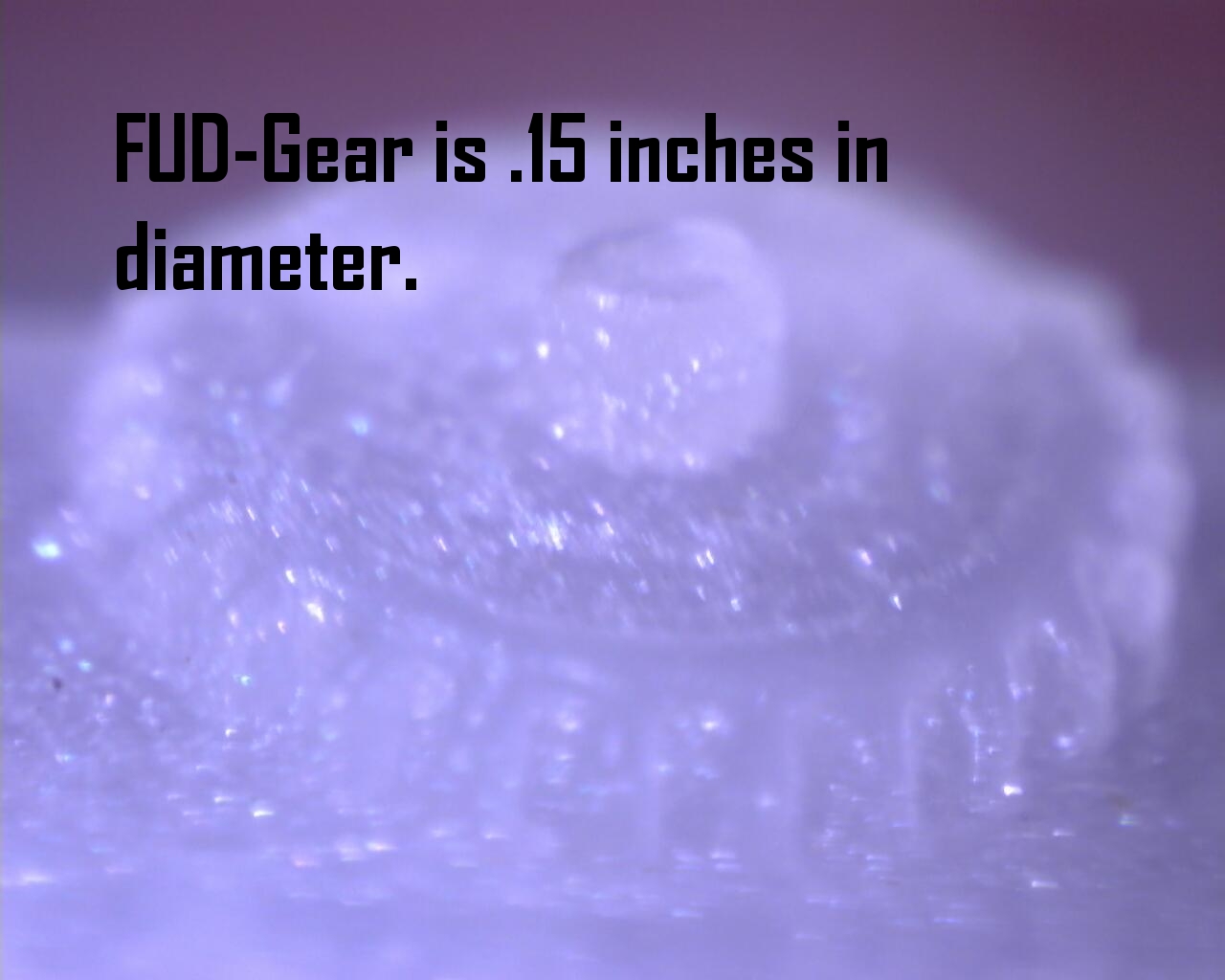

This is a gear I have molded on the top of the Scale workbench that is part of the woodworking machinery model. As .15 inches across, that is great detail.

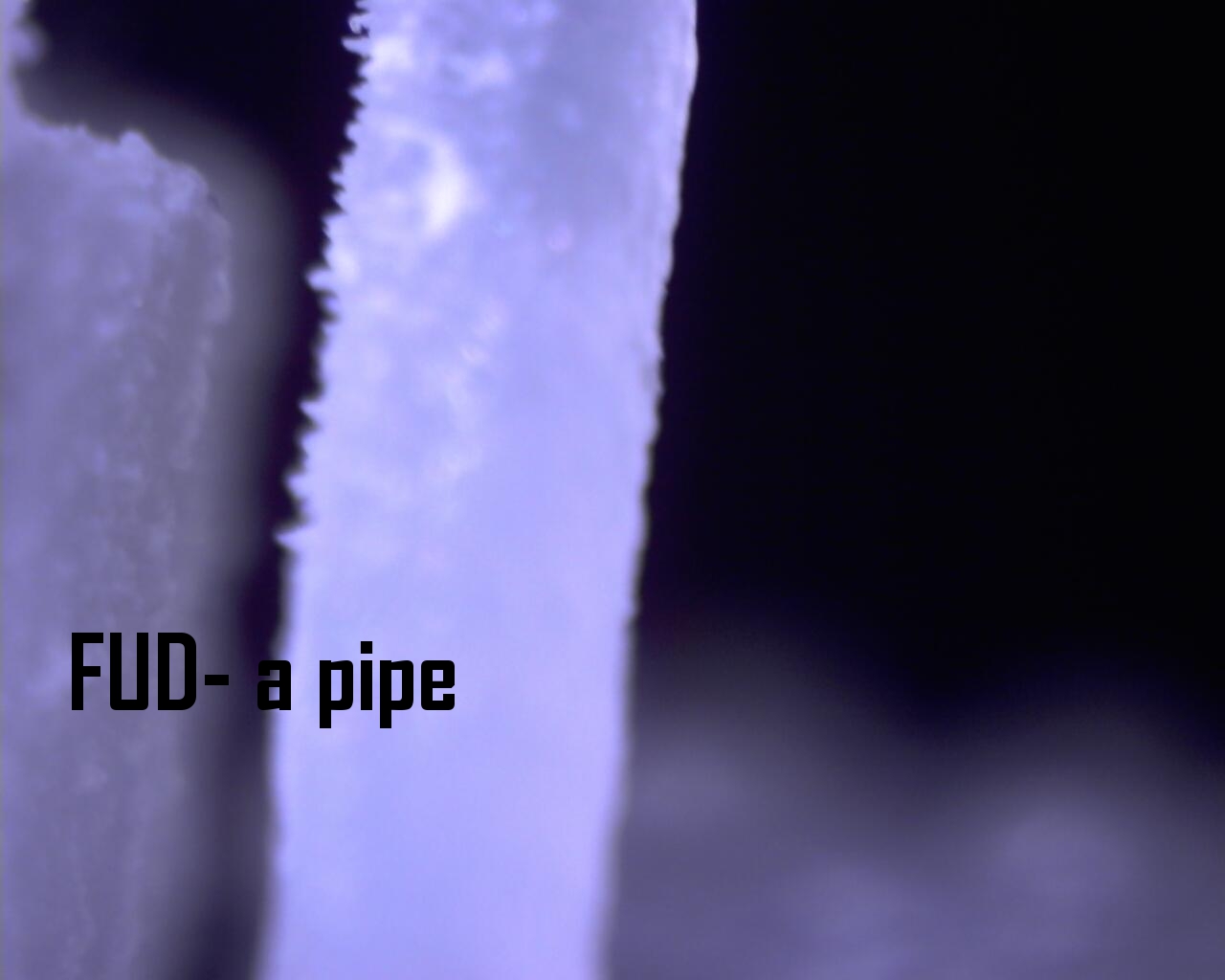

Here is a pipe that is about 2 sscale inches in diameter in HO. You can see where ther is a little resin sticking out. This is an easy clean.

And here is the top point of the whistle that is on the top of that pipe. Pretty smooth.

Every 3D printing technology can have stepping in a printed model, and FUD material is no exception. 3D printing is done in layers and steps can exist between two layers. These two pictures are of S Scale radiators and you can see it. However, this is 100x magnification.

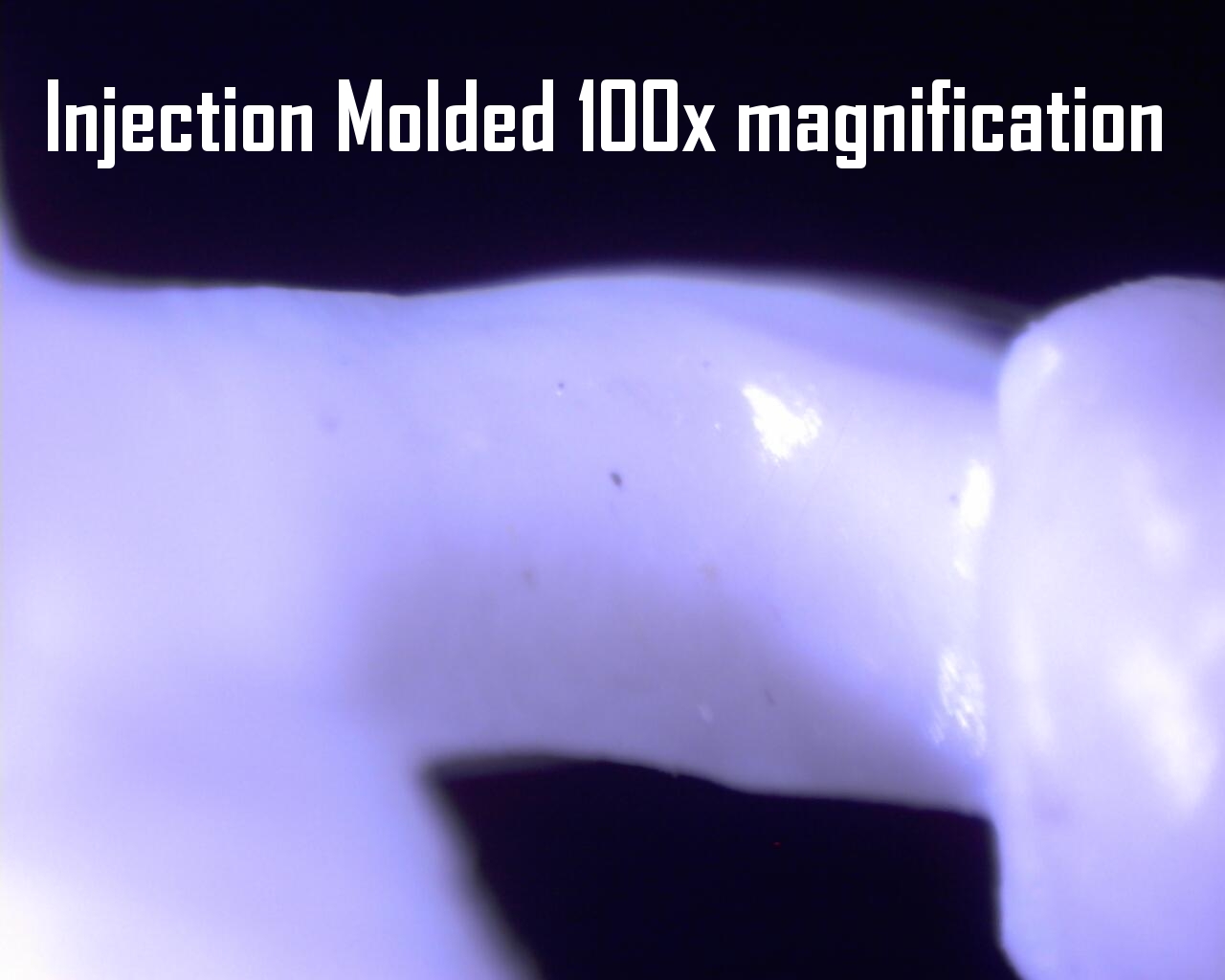

As a comparison, here is a picture of an injection molded item- an arm from a prieser figure.

TEST SECTION

Below is my Shapeways Shop. It lists all the models I have for sale, as well as models I am developing, and ones that I have designed and am waiting for a test print on. It also shows the pricing of various models. As the prices depend on the cubic centemiters of material used, and the price of the material can change, there can be small variations of the price. If you order a product from my Shapeways Shop it is printed by Shapeways and delivered direct to you. I do not handle the model at all, but if there is a problem please contact me.

The shop below is shown in a window. It is probably a lot easier to acces it directly by visiting my shop on the Shapeways site.